Box gutters and overflows

Peter Coll provides a timely update regarding the provision for overflow and box gutter compliance.

In my last article I discussed the emergence of the issue of provision for overflow in external eaves gutters or more specifically, the lack of provision for overflow.

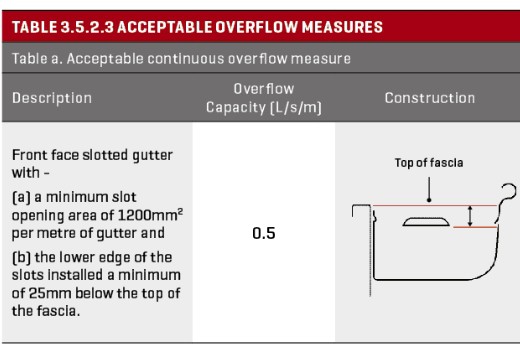

This has become a big issue in the past few months, particularly in Victoria, and is going to be a new section in the upcoming update to the NCC (See what is currently stated in Table 3.5.2.3). This is despite the fact that the Victorian Building Authority (VBA) claims it doesn’t use the BCA code as it believes their regulations are far more thorough and make construction in Victoria of a better standard for the end customer.

As I stated in the previous article, this is not a new addition to the Australian Standards as it has been included for over 15 years. What is new is the strong arm approach the VBA have used to inforce the rectification. VBA has since agreed it could have been handled better.

The authoritative bodies need to learn from the mistakes made by the VBA and work on education first. They need to educate builders, rollformers, roofing companies and even home owners as to “why” this is necessary.

In the previous article I mentioned that this regulation superseded an older clause in AS 2180 – 1986 Metal Rainwater goods – Selection and Installation section 2. Installation, 2.1.2 High-fronted eaves gutters. Where high-fronted eaves gutters are installed, care shall be taken to ensure that water will not flow back into the roof or building structure.

NOTE: Methods of preventing this backflow are as follows:

(a) Provision of slots in the front of the guttering.

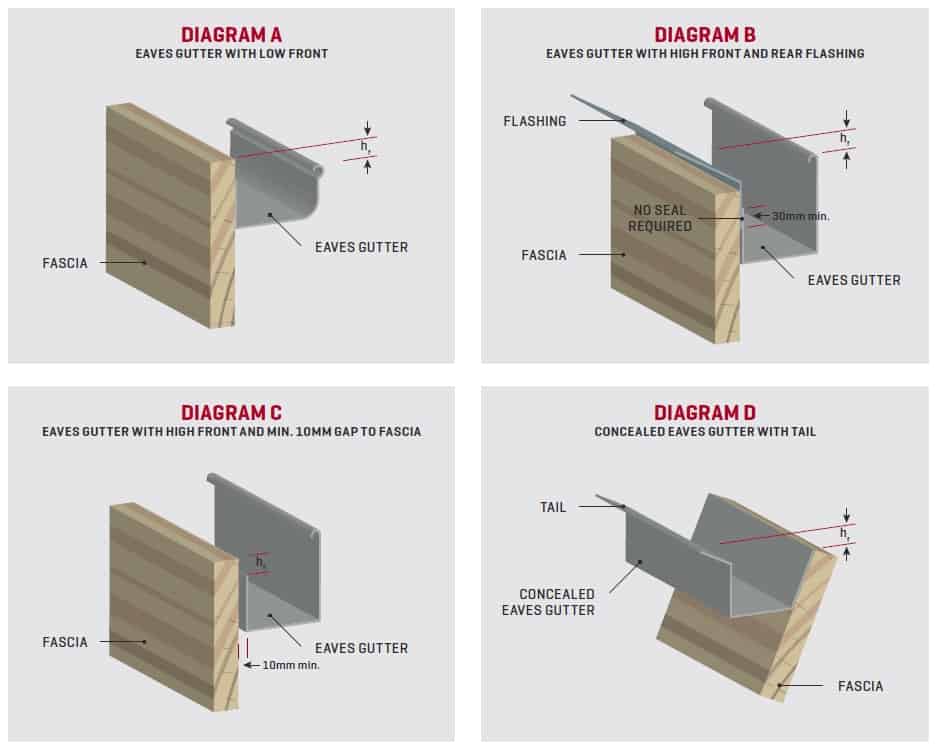

This clause was superseded by: AS/NZS 3500.3.1 – 1998; however the fact that it had been deleted and replaced with AS/NZS 3500.3.2003 Cl3.5.3 was never passed on to the industry. This Standard directs you to Appendix G (See below).

Take particular notice of Diagram C which shows a 10mm gap off the fascia. We have argued with the VBA at length about this gap, it allows for 10,000mm2 of overflow for every metre. To put that into perspective, it is the same as two 100 x 50mm downpipe pops – the most common downpipe pop used in domestic gutter installations – for every metre of gutter.

I met with members from the VBA and members of the Association of Hydraulic Services Consultants Australia (AHSCA) to discuss this regulation. They both agreed that the 10mm gap will in principal not only look bad but the allowance for overflow in a large number of cases will be excessive. The VBA have given BlueScope Lysaght the okay to use a 2mm spacer clip which we believe will provide sufficient provision for overflow, but in my meetings with VBA members, it was agreed that a circumstance could arise when the 2mm or 2000mm2 per metre might not be adequate.

I also discussed this with Mark Alexander from (AHSCA) and he didn’t feel comfortable with a clip that only spaced the gutter 2mm off the fascia unless the job had been hydraulically estimated and proven 2mm was sufficient. He also believed it was leaving the roofing contractor open to litigation.

I told them I was developing a new clipping system for my customers and wanted them to sign off on it before putting it into production. They told me that for my business to be assured it had the best solution for our customers and our business, they would like it to be a minimum of 4mm. That would mean 5000mm2 or one 100 x 50mm downpipe pop per 1.25m of gutter. Both groups thought that this would offer a more broad solution and would provide enough overflow on all domestic dwellings.

I had the pleasure of meeting with Matt Jansen from Stratco where he showed a video of their testing. They set up a rig that used the 1 in 100 year rainfall from Bundaberg: Highest 1 in 100 year rainfall according to them. It saw 340mm per hour over a 5 minute period on a roof that was 16m long by 1m wide (16m2).

Their testing showed that even at the highest rainfall reading in Australia, a 2mm gap will work, but it has no room for error. They recommend a 100% buffer which is a 5mm spacer). This was disputed by AHSCA who stated that the way it was tested in a calm environment and making calculations for the water pressure over a 16m sheet, without actually using a 16m sheet, was a factor.

This test proves in theory that we are working toward a solution. Neil Creek from the Australian Steel Institute and the other rollformers in the meeting asked the question, “If we have this testing done in the correct conditions and ratified by a known expert, will it be accepted?” The VBA agreed. Some of the people in the room were also on the NCC committee and said that this would make its way straight into the code.

BOX GUTTERS

I also took time to look back at an article I wrote about the correct sizing of box gutters and started to look at some of the other problems that contractors are facing such as box gutter compliance.

Plumbers and roofing contractors have been working with builders and supervisors to design effective box gutters while on site but some of the issues that are stated in both Australian Standards and HB39 are things that need to be addressed at the design stage of the production process.

I will outline all of the points that are important in properly designing box gutters to ensure they are installed correctly across the industry.

Extracts taken from SA HB 39:2015 and AS/NZS 3500.3:2015.

SA HB 39:2015 – 5.1 BOX GUTTERS UP TO 600mm

1.1.1 Overflow provision and size

To protect buildings from a total or partial blockage of outlets, downpipes or stormwater drains, it is essential that box gutters discharge all roof water clear of the building via overflows. To ensure that adequate overflow provisions are made and any surcharge is accommodated, the overflow weir of any rainhead is to be 25 mm below the sole of the gutter discharging to the rainhead or alternatively rainheads are to have appropriately sized and positioned overflow provision [see Figure 5.3.1(a)].

Particular attention is to be paid to the following (see Figure 5.3.1):

(a) The size of overflows are to be calculated in accordance with AS/NZS 3500.3.

(b) Overflows are to be terminated in such a way as to prevent damage to buildings and property.

(c) The hydraulic capacity of overflow devices are to be not less than the design flow for the associated gutter outlets, and discharge to atmosphere.

NOTE: For the design of appropriate overflow devices such as rainhead, sump/side overflow and sump/high capacity overflow devices, see AS/NZS 3500.3.

This basically says that you have to allow for sufficient provision for overflow, assuming that all outlets are blocked. Plumbers must ensure that no water can backflow into the house if this happens.

3.7.7.1 Hydraulic capacity

The hydraulic capacity of an overflow device shall be not less than the design flow for the associated gutter outlet. Overflow devices shall discharge to the atmosphere.

This means whatever the flow capacity of the gutter is that the overflow must be able to discharge the amount of water in the event of a 1 in 100 year storm if the downpipe is blocked.

5.3.2 Gutter Installation

(e) Freeboard Box gutters calculated in accordance with AS/NZS 3500.3 include a 30 mm allowance for freeboard to prevent wind driven spillages.

(G) Sizing Box gutters to be sized in accordance with AS/NZS 3500.3 to effectively collect and discharge all roof water with an overflow risk of 1 in 100 y. As an example for commercial or industrial installations, gutters to have a minimum size of not less than 300 mm wide and 75 mm deep at the high end; for domestic installations a minimum size of not less than 200 mm wide and 75 mm deep at the high end commensurate to the roof catchment area serviced by that gutter.

NOTE: Box gutters 200 mm wide are more prone to blockages and should be subject to more frequent inspections and maintenance.

(i) Fall or slope Box gutters to be installed with a minimum uniform fall of 1 in 200 towards the outlet.

This effectively states that all box gutters must allow for 30mm of “freeboard” which is from the overflow point eg. rainhead overflow or specific box gutter overflow must be at least 30mm below the height of the back of the box gutter.

All domestic box gutters must be a minimum of 200mm wide and 75mm deep.

AS/NZS 3500.3: 2015 – 3.7.4 Layout

(e) For the sump/high capacity overflow device, the depth

of the sump (hs) shall be not less than 150 mm regardless of the position of the normal outlet. Changes are not required, provided the sump/side overflow device is used

(G) Box gutters shall—

(i) be straight (without change in direction);

(ii) have a horizontal constant width base (sole) with vertical sides in a cross-section;

(iii) have a constant longitudinal slope between 1:200 and 1:40;

(iv) discharge at the downstream end without change of direction (i.e., not to the side); and

(v) be sealed to the rainheads and sumps.

This section tells us that the (hs) or depth of sump cannot be less than 150mm and it does not matter where the sump is as long as the gutter falls to it and you provide an overflow device.

This next point is a big one and affects a lot of current designs: Box gutters shall be straight (Without change of direction). This means that every box gutter must discharge independently and cannot follow the outline of the building until you find a rainhead. Each box gutter run must discharge independently to ether a sump or directly out of the building without changing the size of the gutter or changing direction.

With building design being so restrictive on space these days, this is the area where designers must think about how the roofing contractor will make the box gutter comply. With this in mind, they must ether allow enough depth in the celling for a sump or allow for the box gutter to discharge in a direct line out of the building without reducing or turning a corner with a chute.

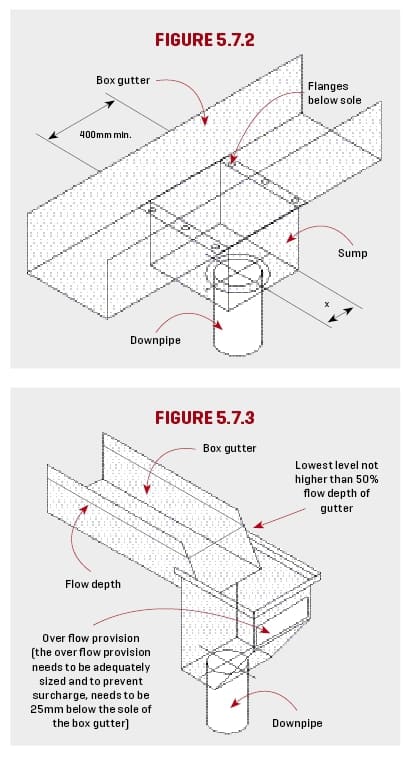

This next section discusses sumps and the correct sizing of sumps.

SA HB 39: 2015 – 5.4.1 Sumps

The sump is to be sealed to the box gutter on all sides (see Figure 5.7.2). The centre-line of the downpipe is to be no further from the nearest vertical side of the sump than either—

(a) the diameter of a circular downpipe; or

(b) the average of the two side dimensions of a rectangular downpipe (see Figure 5.7.2).

Sumps are to be appropriately sized in accordance with AS/NZS 3500.3 with a minimum length of 400 mm and when fitted with a high capacity overflow device with a depth of not less than 150 mm when either one or two box gutters enter the sump.

The minimum size of a sump is 400mm x 200mm (minimum width of box gutter) and 150mm deep.

The outlet must be no further than the diameter of the outlet to the centre of the outlet.

Notes:

1. Dimension X not greater than downpipe size (see Clause 5.3.3).

2. Overflow, sump and gutter support have been left out for clarity.

5.7.3 Rainheads

The purpose of a rainhead is to ensure that, in the event of a blockage or extreme flow conditions, all excess flow is discharged to the outside of the building. The centre-line of the downpipe is to be not further from the nearest vertical side of the rainhead than either—

(a) the diameter of a circular downpipe; or

(b) the average of the two side dimensions of a rectangular downpipe (see Figure 5.7.3). The width of the rainhead is to be at least equal to the width of the box gutter.

This section discusses the correct positioning of rainheads. It states that the highest point of a rainhead cannot be higher than 50% of the overall depth of the box gutter.

The most important point of this section is that you cannot reduce the size of the box gutter to exit the building so we advise keeping the box gutters between 200mm and 300mm wide. The last thing anyone wants is a 600mm wide rainhead on the outside of a building.

After spending extended time with the WS-014-03 committee, VBA, RMRIAV and AHSCA it has become obvious that all of these groups, believe it or not, have the contractors’ best interests at heart.

They all understand that they can be seen as the bad guys more often than not, but they are beginning to understand that education, rather than punishment, on these matters will help to eliminate non-compliance.