Roof trusses: site installation problems

Despite the fact that timber roof trusses have been used in housing construction for the past 30 years or more, there are still frequent reports of problems arising from incorrect installation. here are some more of the on-site issues associated with engineered timber products.

Usually when a problem is first noticed on a building site, the trusses get the blame for being wrong – but a subsequent site inspection by a truss engineer finds a different reason which is often due to incorrect procedures during installation, or site changes made to the trusses to make things fit.

According to MiTek Australia chief engineer NSW Tim Rossiter, the most common issue is that trusses have not been installed straight and plumb, and in their correct position. These details are outlined in the installation guides produced by all nailplate suppliers to be within the tolerances set in AS 4440 Installation of nailplated timber roof trusses.

“When a truss is designed there are assumptions made including that the truss will be in-plane and all in line vertically. Any misalignment in the truss can cause excessive deflection and lead to a wave shape with subsequent buckling,” Tim explains.

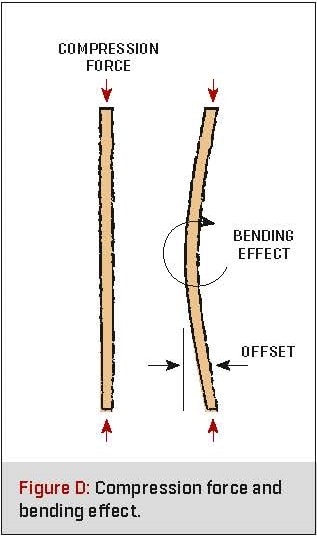

“When a stick of timber is in compression, which is being pushed from the ends, it is quite strong until it starts to bend and buckle. This is because the force changes from just compression to a sideways bending action which gets worse as the offset increases (see Figure D).

“You can see this effect by rolling a piece of paper into a cylinder and placing a small book on top. Because the circular shape does not allow the paper to buckle it will support the book. If the same piece of paper was not rolled but simply stood on its edge the paper would buckle under its own weight.

“The result of a buckling timber member in a roof truss is similar to the paper and it will not perform as designed, potentially leading to a major repair being required.”

Examples of roof plane misalignment are shown (see Images 1, 2 and 3 on page 48) where the top chords are well outside the required limits of straightness and show obvious waves. In Image 1, the truss bracing is straight, which means the trusses were installed in a buckled position and not straightened before final fixing.

The requirements for straightness in AS 4440 are listed as follows.

Plumb – trusses shall be so erected that no part of the truss is out of plumb with at tolerance exceeding the lesser of height/50 and 50mm (see Figure A). For example at a height of 1500mm the truss must not be more than 30mm out of plumb.

Bow – trusses shall be erected with minimal bow, in the truss and in any chord, with a tolerance not exceeding the lesser of length/200 and 50mm (see Figure B). For example a chord of 2000mm in length must not have more than 10mm bow.

It is very important that trusses are installed straight and plumb within these limits, and for them to stay that way after roof loads are applied. They must also be restrained against lateral movement with adequate ties and proper connections.

Another thing to be aware of when looking at roof trusses is the effect of optical illusions that can influence what you see!

In the parallel lines diagram (see Figure C) do you think the lines are straight or bent? If you place a ruler on the page you will find they are actually straight and parallel, not bent as the eyes have indicated.

When sighting a truss member on-site there will be a lot of angled members behind it to create an optical illusion. The best way to check if a truss is bent or deflecting is to use either a string line or a laser level and use the truss support as the datum.

Tim also revealed another common issue, being that trusses are sometimes modified on-site without approval, which can affect the structural integrity of the roof and lead to major problems.

Again AS 4440 covers this situation clearly under Truss Modification which states “under no circumstances shall a truss be modified by cutting, drilling or by any other method that may interfere with its structural integrity, without being approved”.

Some of the more common applications where site modifications have occurred without approval include air-conditioning units, skylights, electrical works and plumbing works.

Sometimes the damage is minor and the repair is simple, but often the damage is critical and the repair requires re-engineering to be done (examples are shown in Images 4, 5, 6 and 7).

Tim commented on one extreme example where a roof was being inspected for certification and it was noticed that the electrical wiring had been passed through 20mm holes drilled in the bottom chords of the trusses which would have significantly reduced their load carrying capacity.

Closer inspection found that two truss bottom chords had been completely cut out from below the air-conditioning fan coil unit, with the unit also suspended by the top chord of the same trusses, and truss webs removed to make space.

As you could imagine, the roof structure was no longer adequate to support the roof loads and considerable rectification work was required.

It is important to understand that timber trusses are engineered components and should be treated with respect. Modifications must never be undertaken unless the rectification has been detailed by a certified and qualified engineer, preferably arranged through the truss fabricator that supplied the trusses.

Make sure no-one on your building site contravenes the requirements of AS 4440, to ensure the job has a guarantee of performance and will perform for the life of the building.