Double glazing in Australia

There are many misconceptions about double glazing: how it works, where to use it, what purpose it fulfils and whether it is worth the extra cost. Gary Smith gives Building Connection a run-down.

Travelling the country and experiencing all of our climate zones first hand, I frequently hear comments like “our climate is warm so we don’t need it” or “we have a moderate temperature so don’t need it”. On the opposite side of the scale, I have heard people in colder climates say “it doesn’t work”. I want to try and make the use of double glazing simple.

The first misconception about double glazing is the actual use of the term and whether it is the correct terminology used in context.

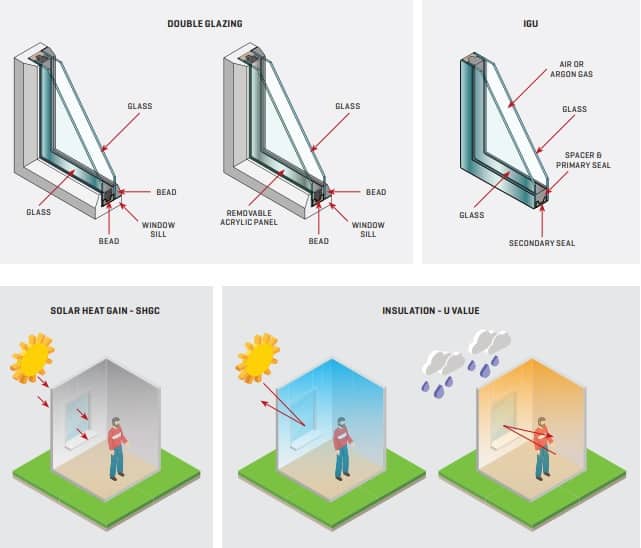

‘Double glazing’ is an overall term that refers to various types of two-pane glazing. More commonly, the term double glazing is used to describe:

- A dual window system that gives benefits in acoustic performance and energy efficiency – often referred to as double glazing because it literally has two pieces of glass.

- A situation where a secondary piece of glass or an acrylic system has been installed into an existing window which also gives benefits in acoustic performance and energy efficiency.

- An Insulated Glass Unit (IGU) which is a hermetically sealed unit. This means in between the glass panes is a sealed environment which ensures great insulation and no condensation between the glass. IGUs are used mainly for insulation. However, the right make up will also impact the acoustic performance.

Dual window systems

These are generally used in areas where the issue is noise. We see many areas in fl ight paths and around new toll ways installing secondary window systems. The system works in two ways. The introduction of another window with thicker glass provides a barrier to the sound and if an air space of over 100mm is achieved then this has a positive impact on the acoustic performance.

Double glazing

This type of system is mostly used in retrofit situations and there are two types seen in Australia. The first is when another piece of glass is installed in front or behind the existing glass by inserting a bead, hopefully some type of desiccant, and then sealing in a new piece of glass. This type of system that is non-removable is prone to condensation between the glass panes due to the seal not being sufficient for a long period of time. Often the desiccant becomes saturated quickly and then condensation begins to form. This is not a recommended option unless being carried out by a company experienced in this type of installation.

Secondly, acrylic installation systems are installed inside the window system often by some type of magnetic system. They can be removed to enable cleaning and ventilation of the home when required. Because of this, the issue with condensation between the existing glass and the acrylic panel doesn’t occur. These are a great retrofit solution to improve energy and acoustic performance of windows.

Insulated glass unit (IGU)

IGUs are the most commonly used double glazed system. As the name indicates, these are specifically designed for energy performance. The units are manufactured as a completed unit and are then inserted into a window system that is capable of accommodating the unit. The units commonly have a spacer, primary seal and then a secondary seal although there are some variations to this. This sealing procedure makes the IGU a hermetically sealed unit so it has a dry contained environment inside, improving the insulation performance and eliminating condensation inside the unit. If you have an IGU with condensation in the air space then it has failed and needs replacement.

I want to focus this article on Insulated Glass Units from here on and explain how they function, how they can be tailor made to perform different functions and why you would want to use them.

Function

A friend of mine refers to IGUs as a speed hump, they are put in place and slow down the transfer of heat. In the most basic form, an IGU works just like ceiling insulation: it holds air which is better to slow heat transfer than a piece of clear glass. In this basic form – clear glass, air space, clear glass – it is the air space that is the insulator.

Glazing reacts thermally in two different ways: heat transfer due to a difference in temperature from inside to outside the building and solar radiation passing through the glass creating heat.

The measurements for these are U Value and Solar Heat Gain Coefficient (SHGC). The lower the U Value the better the insulation performance and the lower the SHGC the less solar radiation passing through.

A tailor made IGU

If you want to alter the function of the IGU, you can do many things: change the glass type to a Low E, alter the size of the air space or add argon gas to improve the U Value. To lower the amount of solar heat gain, simply add tinted glass products and Low E to the IGU. To improve the acoustic values, include heavier glass, laminated glass and have a 40% difference in the two glass thicknesses. For example use a 6mm laminated acoustic glass product with 4mm glass in the IGU. To make the product secure and safe, include laminated safety glass designed for higher security. The options are countless with IGUs to tailor them for the function you require.

I often tell people it is a bit like visiting Subway and creating just about whatever you like.

Which IGU to use

In colder climates you want to get the U Value as low as you can afford and have the SHGC high to allow the free energy from the sun to enter the home especially on the north with correct eave protection. This can be achieved by using clear glass, neutral Low E glasses and argon gas. It may be appropriate to reduce the SHGC on east and west elevations depending on the building design.

In warmer climates you want to get the U Value as low as you can afford and reduce the SHGC to restrict the heat gain from the sun. This can be achieved by using tinted glass, tinted Low E and argon gas.

Remember, insulation is important in air conditioned and heated buildings. No matter the climate, IGUs are an appropriate energy efficient solution and just need to be tailored to suit the climate and elevation.

For acoustic performance in IGUs, the air space will not have an impact, so alter the glass types being used and vary the two thicknesses by 40%, use special laminated acoustic glass products and remember – the thicker the glass the better it will perform.

For security and safety, use glass products in the IGU that are developed for these purposes such as A Grade safety glass and special laminates.

It is important to understand that when you install an IGU into a window system, the window system will impact on the performance of the IGU. There are window systems designed specifi cally for all areas of performance.

Why use an IGU

An IGU is still the best solution around the world for varying performance requirements and has been for many years. The use of IGUs in the right window system will significantly reduce the need for heating and cooling in a building, reducing energy costs. I can say through experience visiting many homes that have used IGUs, the payback for the investment is instant as you feel the difference in the comfort of the home. There are some websites worth visiting with lots more information on energy efficient glazing products: www.efficientglazing.net and www.wers.net.