Building a passive house

There are several techniques that can be used when designing a home to ensure it is naturally cooler in summer and warmer in winter. Clare Parry clarifies the confusion surrounding passive house design and explains how builders can become experts in this area.

Mention the term ‘Passivhaus’ to any building professional and you may get an array of responses or a barrage of questions: an unnecessarily strict demand that takes efficiency too far; an unnecessary remedy for a problem we don’t have; or perhaps the panacea for all our building woes.

So what is it all about, really – is it something new, something different, or both?

The Passivhaus (or Passive House) design standard is effectively a guarantee of build quality. Being an ‘as-built’ standard it has marked benefits over the often applied design-only standards prevalent among our many building codes and guidelines. The English translation of Passive House can cause some confusion, with the literal translation to ‘house’ not picking up the implied meaning of ‘building’, and the common misconception that it is the same as Passive Solar design. Due to this, even English literature often uses the German version of the name.

The Passivhaus standard came of age fairly recently in Europe, with the first official Passivhaus opened in Germany in 1992. This row of four terrace houses is still operating, achieving excellent internal comfort without the use of any major heating and/or cooling equipment. In southern Germany’s often freezing climate (which can reach temperatures of -25˚C), this is no mean feat.

The Passivhaus design principles have since been widely adopted, developed and even enshrined in the local building regulations in some regions. Based around the principles of the international thermal comfort standard ISO 7730, Passivhaus is essentially an ultra-low energy standard. Compared to typical buildings, a Passivhaus building is predicted to consume up to 75-90% less energy in operation. The core concept of Passivhaus is providing a truly energy efficient and comfortable building while maintaining a focus on affordability.

A Passivhaus building must meet three key criteria to achieve certification:

- Minimised demand for heating and cooling.

- Air tightness of the building.

- Significantly reduced whole building energy use.

In technical terms, Passivhaus is defined by the following characteristics. This is for most climates and there are some modifications for extreme, hot and/or humid climates or some building types

- Heating/cooling demand: 15kWh/m2 per annum; OR heating/cooling load: 10W/m2.

- Airtightness: 0.6 air changes per hour in a building positively pressurised to 50 Pascals (0.6 h-1 at n50).

- Total Primary Energy Demand: 120kWh/m2 per annum (the energy allowance for the whole building, including plug loads). The term ‘Primary Energy’ refers to energy in its raw form, e.g. coal. This takes into account the input power required to generate the power we actually use.

Using default European figures, the allowance of 120kWh/m2 of primary energy translates to an allowance of 46kWh/m2 per annum at the building. Although there are no requirements to consider sustainability of materials or embodied energy, a project that targets holistic sustainability may include these elements, alongside complementary factors such as water, transport and biodiversity.

While the real figure is unknown, it is estimated that there are more than 50,000 Passivhaus buildings around the world. Only around 6000 have attained the official Certified Passivhaus tag, with the majority of buildings happily functioning without the official stamp of approval. Indeed, many of the more pioneering buildings have been left unstamped. Anecdotally, there may be more than one Passivhaus building in Australia, and there will soon be at least one certified project.

Among the number of realised Passivhaus projects internationally, significant projects include the world’s first high-rise office building, the RHW.2 building in Vienna, Austria. This building, completed in 2013, houses 900 staff and maintains many of the design principles typical for high rise office buildings, such as full-height glazing and open plan offices.

The Bushbury Hill Primary School was one of the first Passivhaus schools to be built in the United Kingdom, catering for 150 students. The project met the Passivhaus criteria with a strict fixed budget, focusing on optimising a simple design. The outcomes for the client have been credible and genuine, with the principal reporting excellent occupant satisfaction and beneficial learning outcomes.

At the Monte Rosa Alpine Hut, a Passivhaus ski lodge with no active heating system, there have been recorded temperatures down to -40˚C but the temperatures inside are maintained at a comfortable 20˚C.

Passive house in Australia

Design teams have adapted their techniques to different building types and climate zones, across the globe, drawing on Passivhaus principles. What is it that makes this standard so successful and what can be learned from an Australian perspective?

In Australia, sadly, we are falling behind in our application of low-energy standards. And while we have a multitude of tools available Passivhaus is the strongest yet to actually ensure the realisation of a high-performance building.

Passivhaus buildings around the world have been resounding successes. From the Arctic to the Antarctic, as well as hot climates, such as Spain, Mexico, Greece and Indonesia, Passivhaus projects have been established. Clearly, Passivhaus can be applied across all climate zones.

These are climates where the extremes of cold or hot make life very uncomfortable, and buildings need to provide refuge and relief. In Australia’s generally more temperate climates, Passivhaus is theoretically easier to achieve.

‘Fabric first’ approach to design

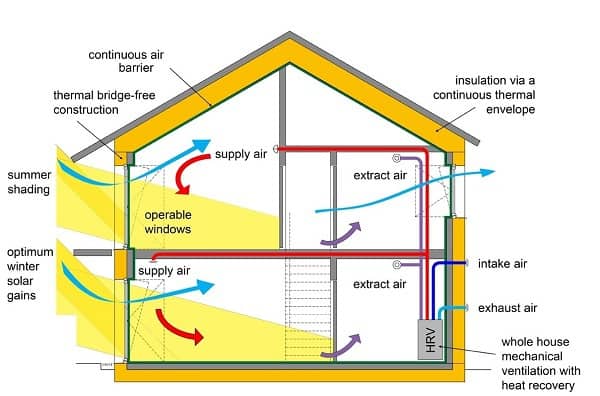

‘Without compromise’ is the mantra for the Passivhaus approach to design: thermal bridges are eliminated, insulation is wrapped carefully around every surface of the building and airtightness is a key concern. There are no single glazed aluminium windows.

In southern Australian climates, it is possible to build a compliant Passivhaus dwelling with just moderate increases on the minimum compliance levels of insulation.

Depending on the expanse of glazing, orientation and available shading, it is likely that the window specification (glass and frame) required will fall somewhere between a U-value of 1.4 and 2.0. While not available from every supplier, the local glazing market is catching up with renewed interest in developing the high-performance end of the window market.

Of the three defined Passivhaus criteria, the most difficult to realise is usually the building airtightness. In a leaky building, air infiltration can account for as much as 50% of the heating and air-conditioning loads and accounts for most of the discomfort due to draughts or excessive heat gains. A typical Australian home built before 2000 would likely achieve an airtightness test result in the realm of 10 air changes per hour (ACH), measured in a pressurised building (to 50Pa), and in many homes this can be up to 25 ACH. Achieving this may require careful use of appropriate layers, tapes and/or vapour membranes to form a continuous airtight barrier.

Importance of eliminating thermal bridges

A thermal bridge is a localised weakness or inconsistency in the insulation barrier, where the heat flow is different (usually increased) in comparison with adjacent areas.

Thermal bridges most commonly occur across window frames, structural members, penetrations of the building fabric (e.g. pipe or ductwork) and at junctions of the building fabric, such as where a wall meets a floor or ceiling.

In winter the heat we are pumping into our building is lost when it flows out across window frames, for example. In summer the reverse happens with heat from outside being transferred inside to counter the work done by air-conditioning systems.

When tallied up across a whole building, these small thermal losses can result in significant energy loads, with potential for high energy (kWh) and financial impacts. Thermal bridges can also lead to moisture penetration in building components, condensation and mould growth.

Integrated design and quality control

Unlike many building rating and certification tools, the ultimate aim of building to the Passivhaus standard is not necessarily the final certification, but rather to achieve exactly what the standard promises to deliver: a comfortable, high quality, healthy building that costs very little to run. The certification represents a verified and marketable result. Looking forward, the driver for success of Passivhaus will be market recognition of its benefits, whereby the capital investment becomes worthwhile given an identifiable return.

The key to achieving Passivhaus on any building is its full integration into the design and construct process; it is impossible to ‘add-on’. For the client, this means getting expert advice early, and for the design team, this means getting everyone together from the concept stage to ensure that the aesthetics, functionality and constructability do not conflict.

The following certifications are available for Passivhaus professionals and building components:

- Certified Passive House designer or consultant – Design professionals, likely an architect or engineer, with expertise relating to the application of the Passivhaus standard and the ability to work with the PHPP tool.

- Certified Passive House tradesperson – Builders and tradespeople who have been trained to apply the exacting requirements.

- Certified Passive House components – High performance building components including window frames, glazing, skylights, external doors, curtain walling, wall panels, insulation, heat pumps and ventilation systems.

- Certified Passive Houses – A completed building that has been certified as meeting the Passivhaus standard.

It should be noted that a Passive House can be realised and certified without the use of certified designers, consultants, tradespeople or products. These certifications have been established to provide clear direction in the market, but are not prerequisites to success.

The engagement of a certified Passive House designer and/or tradesperson would be an added benefit to any project, with such professionals having demonstrated the required knowledge and expertise to prepare and execute a design according to the stringent requirements of the standard.

Cost and ease of build

With the first projects in Australia currently in various stages of design and construction, information on costs is not yet readily available. With many of the pioneering residential projects sitting at the ‘luxury’ end of the market it will also be difficult to equate this to a typical dwelling.

Long-term tracking data from Europe, as part of the Passive-On project, shows that a residential Passivhaus project is likely to require between 3-8% more in upfront costs; however many projects have been completed with no additional investment. Additional costs are recouped through lower operating costs, usually in five years or less.

The additional investment in materials such as insulation is partially offset by the significant reduction, or even elimination, of heating and air-conditioning systems, for example.

With the health, wellbeing and comfort measures introduced by the stringent build quality, there are many benefits that also cannot easily be quantified. Applications of the standard in health care, education, aged care and social housing could have widespread benefits.

The current unknown factors in building to the Passivhaus standard in Australia are the availability of specialist products and materials, and the availability of skilled tradespeople and builders. The former is improving steadily; there are now a number of Passivhaus-specific product suppliers and companies already in Australia whose overseas offerings include appropriate products are starting to make them available locally, due to the persistence of consumers.

The number of builders and tradespeople is increasing much more slowly, with current supply well short of meeting demand. The main difference from the construction perspective is putting in place the appropriate processes and taking the time to ensure that the build quality is appropriate, in order to achieve a building that is airtight and free from thermal bridges.

Conclusion

Any good building is designed around providing not just an aesthetically pleasing structure, but the essential provisions of comfort, shelter and a healthy indoor environment. As we move into a more sustainable future, the hefty building systems, associated energy bills and greenhouse gas emissions must also be considered.

When adopted as part of an integrated approach, the Passivhaus standard ensures comfort, energy efficiency, excellent air quality and low operating costs through just three major areas of focus – insulating right, good building sealing and reducing total electrical loads. The standard is about the very basic elements of building well and, with the core elements based in physics, is backed up by decades of research and real world, exemplar projects.

With advantages including an enhanced quality of life and future-proofing from energy price escalation, Passivhaus has established itself as the leading international standard for comfortable, healthy and affordable low-energy buildings.