Unlocking the potential of new and improved materials in construction

Fiber-Reinforced Polymer (FRP) composite bars have emerged as a potential game-changer for construction, particularly in concrete structures built around coastal areas, in aggressive environments and in electromagnetic applications. Easy to transport, handle and assemble, these reinforcements are a sensible alternative when compared to heavyweight materials such as steel.

The sustainable qualities of construction materials are becoming equally important, resulting in a push for cement and concrete production processes with reduced carbon emissions.

Lightweight marvels

Some key standout features of FRP bars are their high tensile strength and low weight. These features have the potential to not only ease construction logistics but also significantly reduces the demand for manpower during installation. Unlike steel and other conventional materials requiring two individuals to handle, FRPs typically require only one, streamlining the construction process and enhancing overall efficiency.

Flexibility enleashed

FRP bars feature flexibility, high tensile strength, and long durability, and are non-corrodible. They are non-metallic and therefore will not interfere with the operation of sensitive electronic devices. Moreover, FRP bars have a lesser economic and environmental footprint than steel bars as the latter are energy intensive to produce.

These properties make FRP bars a promising solution for reinforcing concrete elements like beams, columns, slabs, pavements, and foundations to achieve a net-zero infrastructure.

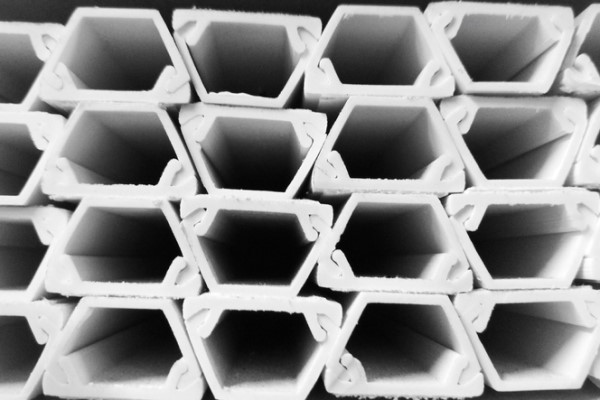

The new standard AS 5204:2023– Fibre-reinforced polymer bars, published in December 2023, outlines the requirements for acceptable materials used in the production of glass and basalt fibre-reinforced polymer (FRP) bars. These bars are employed for internal and non-prestressed reinforcement in concrete, whether in the form of straight or bent bars.

FRPs boast an impressive strength-to-weight ratio

FRPs offer a possible performance advantage, boasting a weight-to-strength ratio that surpasses steel alloy by tenfold and exceeds the strength of reinforcing steel by two to three times. This ratio emphasises the advantage of opting for a material that provides robust structural reinforcement without adding unnecessary weight – a crucial consideration in construction projects.

In addition, FRP bars can be an ideal reinforcement material to use in areas of high salinity, as evidenced in mining operations and in structures near coastal zones. These include water retaining structures, sewer plants, wharves, jetties, and boat ramps.

FRP bars can also be a reinforcement option in concrete structures around electromagnetically sensitive areas.

As the construction industry evolves, leveraging these advantages will continue to be a consideration to construction professionals to optimise efficiency, reduce costs and their carbon footprint, and ensure the longevity of their structures.

Standards towards sustainable cement

The move towards sustainable materials in building and construction is underway – industry and businesses are conscious of procuring and using materials that are sustainably sourced or with a reduced carbon footprint.

The benefit to builders with the revision to AS 3972 General purpose and blended cements, is that the changes give guidance on options for construction materials to enable them to offer what customers are looking for- cement and concrete that are geared towards net zero goals.

These goals are aligned with the Decarbonisation Pathway for the Australian Cement and Concrete industry which has identified critical pathways needed to lower CO2 emissions through significant technological, structural, and behavioural changes.

The recommendations in achieving this include:

- Increased use of established supplementary cementing materials (SCM) such as fly, ash, slag, amorphous silica and limestone

- New manufactured pozzolan SCMs such as lithium by-products and calcined clays

- Increased use of limestone mineral addition to replace clinker in manufactured cements

- New clinker-efficient composite cements

These changes will require the revision of Australian Standards to support changes to cements being used currently, to introduce low-carbon cements. It is estimated changing the composition of the cement used will help reduce CO2 emissions by 2.5% by 2025, and by 10% by 2050, contributing to Australia’s targeted net zero goals by 2050.