RMIT engineers make strong compressible material inspired by sea sponge

RMIT University engineers have developed a material with compressive strength and stiffness to improve architectural and product designs. The double lattice design was inspired by the skeleton of a deep sea sponge.

Lead author Dr Jiaming Ma says that extensive testing and optimisation shows the pattern’s combination of stiffness and strength when it can contract when compressed.

Most materials get thinner when they are stretched or thicker when squished where auxetics do the opposite. Auxetics can absorb and distribute impact energy effectively.

“Each lattice on its own has traditional deformation behaviour, but if you combine them as nature does in the deep-sea sponge, then it regulates itself and holds its form and outperforms similar materials by quite a significant margin,” Dr Jiaming says.

Results published in Composite Structured shows the same amount of material usage has the lattice 13 times stiffer than auxetic materials based on re-enterant honeycomb designs. It can absorb 10% more energy with a 60% greater strain range.

“This bioinspired auxetic lattice provides the most solid foundation yet for us to develop next generation sustainable building,” Dr Ngoc San Ha says.

“Our auxetic metamaterial with high stiffness and energy absorption could offer significant benefits across multiple sectors, from construction materials to protective equipment and sports gear or medical applications,” he said.

The bioinspired lattice structure could work as a steel building frame to allow less steel and concrete to be used to get similar results as a traditional frame.

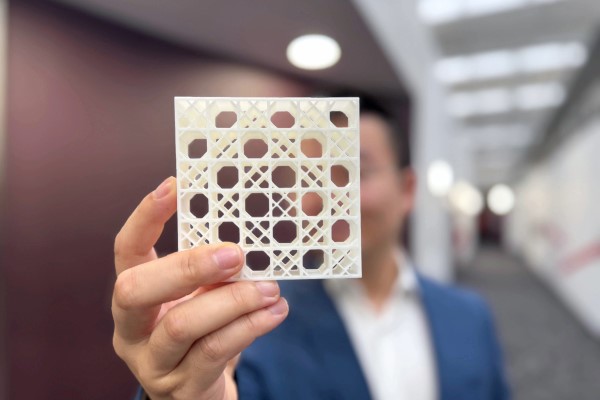

The design has been tested by RMITs’s Center for Innovative Structures and Materials using computer simulation and lab testing on a 3D printed sample made from thermoplastic polyurethane. The plan is to produce steel versions of the design for use in concrete and rammed earth structures.

The team is also planning on integrating the design with machine learning algorithms for future optimisation and to create programmable materials.

“While this design could have promising applications in sports equipment, PPE and medical applications, our main focus is on the building and construction aspect,” Dr Jiaming says.

“We’re developing a more sustainable building material by using our design’s unique combination of outstanding auxeticity, stiffness and energy absorption to reduce steel and cement usage in construction. Its auxetic and energy-absorbing features could also help dampen vibrations during earthquakes.”