Building product certification explained

The Australian building industry is highly regulated, yet incidents of non-conforming or noncompliant products being used on building sites still occur and have prompted changes to the CodeMark certification scheme. Adelle King explains the changes and what building contractors need to know about the product certification process.

In August 2017, implementation of the improved CodeMark Australia certification scheme commenced following an extensive review process conducted by the Australian Building Codes Board (ABCB). The review was in response to concerns about growing incidents of non-conforming and non-compliant products in Australia.

CodeMark is a voluntary third-party building product certification scheme that provides compliance of building materials, forms of construction and designs under the Building Code of Australia (BCA) Volumes One and Two. Products certified under CodeMark are recognised nationally as being compliant with specific requirements of the BCA.

In 2014, a senate inquiry into nonconforming and non-compliant products lead to a review of the CodeMark scheme in consultation with State and Territory governments, industry groups, Scheme Certification Bodies and the Ministry of Business and Innovation and Employment in New Zealand.

The review recommended several ways CodeMark could be strengthened, including separating the Australian and New Zealand schemes. The schemes have now been re-named in Australia and New Zealand to CodeMark Australia and CodeMark New Zealand respectively to reflect the fact that although CodeMark was developed jointly between the two countries, the schemes now operate and are administered separately.

CodeMark Australia has introduced requirements for more information to be included about the products that have been certified and there will now be information included about how the products are to be used. Additionally, performance requirements must now be evaluated in accordance with CodeMark protocol for the assessment of products against BCA Performance Requirements. The tests and reports on which the accredited certification body based its decision are required to be presented and the manufacturing facility where the products were made must be identified.

The ABCB felt these changes would establish a common approach and provide greater clarity for end-users following feedback from stakeholders during the review process that identified concerns about the level of discretion available to accredited certification bodies (CBs) in their certification process.

Other changes include the removal of risk analysis, the removal of mandatory factory or site visits, the introduction of post manufacture or supply chain surveillance and a new Certificate of Conformity template.

The ABCB says the new Certificate of Conformity template will make it easier for practitioners to prescribe the amount and clarity of information required in the certificate and to determine which parts of the BCA the product has been certified to meet. The new scheme will be implemented over a period of time so the industry can adjust and the transition be made for existing CodeMark participants and certified products.

Accredited bodies have until January 2018 to prove to the Scheme Administrator and Accreditation Body for CodeMark, the Joint Accreditation System of Australia and New Zealand (JAS-ANZ), that they have complied with all the new requirements of the scheme.

JAS-ANZ will also host a product database, which was previously on the ABCB website, with downloadable Certificates of Conformity available.

The certification process

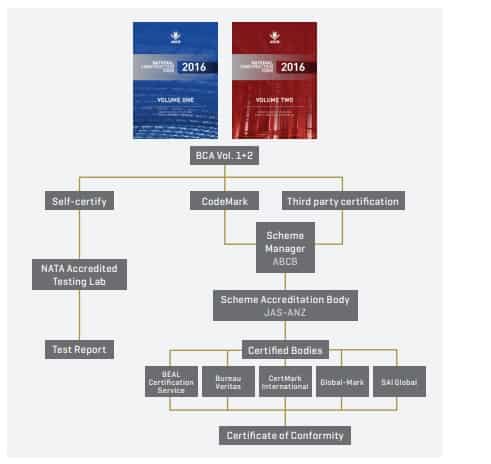

The ABCB manages the CodeMark scheme in Australia but JAS-ANZ is the scheme accreditation body, meaning it assesses and accredits certification bodies that issue Certificates of Conformity in relation to a product.

JAS-ANZ has developed assessment criteria that CBs must meet to become accredited and conducts audits of these bodies every six to 12 months to ensure they comply. As of writing there are five CBs accredited to certify to the BCA under the CodeMark Scheme in Australia, BEAL Certification Service, Bureau Veritas, CertMark International, Global-Mark and SAI Global.

The tests, factory visits and costs for CodeMark certification will differ depending on the CB so companies wishing to gain CodeMark should contact the CBs directly through the details available on the JAS-ANZ website to find out how to proceed.

The six CodeMark CBs are responsible for evaluating products, including reviewing the test reports and, where applicable, auditing the manufacturer or installation site for compliance. If the product is found to comply with the specified sections or clauses of the BCA then a Certificate of Conformity is issued, which lists the scope of compliance and any limitations or conditions.

While all building products and systems must comply with the BCA under Australian law, CodeMark certification itself isn’t mandatory, which means people can choose to get their products assessed and fit to be certified under a number of different schemes.

“The main difference between CodeMark certification and other Product Certification Schemes is that CodeMark is a nationally recognised scheme. The CodeMark Certificate of Conformity is one of several options available for meeting the ‘Evidence of Suitability’ requirements of the BCA. However, unlike other Evidence of Suitability options, Certificates of Conformity receive mandatory acceptance under State and Territory building control legislation. This means that CodeMark certified products do not require additional information from local councils or other regulatory bodies because they accept that the product has gone through extensive third-party assessment,” says Bureau Veritas certifi cation manager Sam Guindi.

“Another distinguishing element of CodeMark is that it includes installation as part of the assessment process. Traditional product certification schemes certify how the product is manufactured in the factory to ensure it complies with the requirements of the relevant Standard but CodeMark also looks at installation because if the product isn’t installed correctly onsite, then it’s useless. The Certification Process must examine the Product, its uses and installation (including, if applicable, conducting a construction site visit) to determine the on-site application of the Product.”

Under the CodeMark Scheme, compliance with the BCA is achieved by satisfying the Performance Requirements. The performance based format of the BCA allows a choice of deemed-to-satisfy solutions (DTS) or flexibility to develop performance solutions based on existing or new innovative products, systems and designs. The performance requirements can be satisfied through a performance solution (formerly known as alternative solution) or DTS or a combination of both.

“DTS Solution means a method of satisfying the Deemed-to-Satisfy Provisions, e.g. the product has already been tested in accordance with a referenced Standard or Test Method and hence compliance with the Performance Requirements of the BCA has been demonstrated,” says Sam.

“If the product cannot be assessed under the DTS solution, CBs can still assess and certify the product under the performance solution, provided the product will meet the performance requirements of the BCA. However, it’s a more complex process assessing a product against a performance solution compared to a DTS solution.”

Once a product has been identified as complying with the requirements of the BCA, a Certificate of Conformity is issued. This certificate has a three year life, after which an audit and full review are conducted. CodeMark certification shows a product has been assessed by an independent third-party certifier, offering increased credibility and market potential.

“CodeMark certification isn’t just a test report, it’s an ongoing product compliance scheme that ensures every product that comes out of the factory will comply because we’ve audited the system, we know the company is doing the right thing and we do surveillance audits to ensure this,” says Sam.

Alternative certification options

Since CodeMark isn’t mandatory, companies that want to sell and market a product in Australia have a number of options, including to self-certify or go through an alternative certification scheme.

Self-certifying involves having the product tested and receiving a test report that shows the product complies with specific BCA requirements.

“A test report is not third-party certification. The test report basically states that the prototype sent to the laboratory on the day passed testing but there are no guarantees this product is what the factory will continue to manufacture and supply,” says Sam.

Third-party product certification schemes, on the other hand, verify testing of the product as well as auditing the manufacturing facility. CodeMark is not the only third-party certification scheme and most CodeMark CBs also have their own product certification schemes that complement CodeMark.

Whereas CodeMark represents compliance with specific requirements of the BCA, these alternative product certification schemes show compliance with specific Australian or international standards, which may also be referenced in the BCA.

Bureau Veritas, for instance, certifies products under its ‘S’ Mark Scheme, which was originally established by Standards New Zealand in 1944 before being taken over by Bureau Veritas in 1997.

The ‘S’ Mark is associated with a range of products from safety footwear and protective clothing to timber products and fire hydrants.

“Companies will come to us with a product that needs to comply with a specific Standard so we audit the manufacturing process and verify test reports against that Standard,” says Sam.

“It’s quite a straight-forward process because the testing requirements are outlined in the Standard so we assess the product against that and then issue a Certificate against the particular Standard.”

Due to the number of different ways building products can receive certification in Australia, there can be some confusion about how and when a product complies.

“We could have a client that receives certification on a product for fire properties but there could be instances where the product may also require assessment against other properties, such as thermal properties, so building contractors need to be checking the Certificate of Conformity for the scope of compliance, installation requirements and limitations,” says Sam.

“There is also sometimes confusion when people assume that because a company has certification on a particular product, it means all their products comply but product certification is very specific to the product listed on the Certificate of Conformity. While certification is evidence of compliance with the BCA or with a specific Standard, it’s still important to check the content of the certificate to know the extent of that compliance.”