Waterproofing rules: part 2

WATERPROOFING RULES: PART 1 looked at the main principles of waterproofing we all should know or be able to find quickly. This second part by Jerry Tyrrell delves further into the detail…

My 40th article in the past 10 years will be short. My key point is: read Part 1 again – and don’t be distracted by any unstructured information, or endless technical detail that you won’t remember. Lock onto the principles of waterproofing in the same way that you learned your ABCs, or the rules of grammar. The detail in this article should make it easier to implement what was said in Part 1 on all your projects.

Itty, bitty stuff

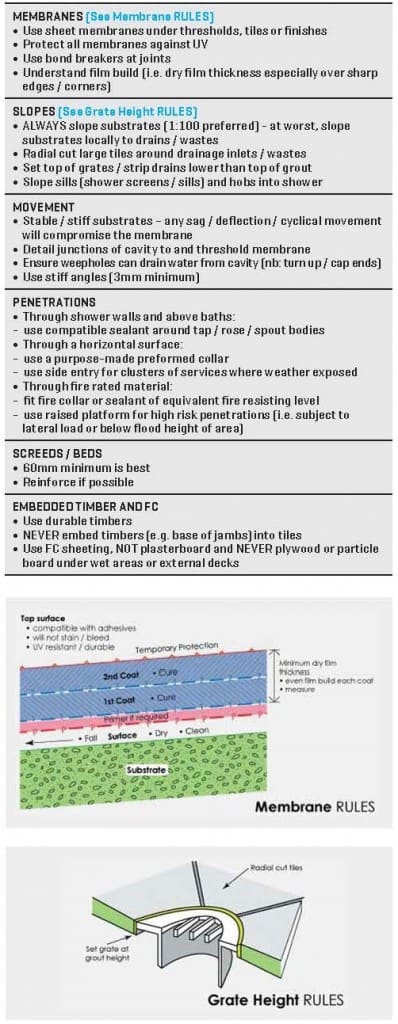

Waterproofing is a very technical business and I don’t want to limit your choices by telling you to use specific products (some of which may have been improved upon or superseded). When I started building, it was all ‘slap a bit of blackjack on it’ and drained flashings. Then acrylic shower membranes were carelessly thrown at us, and the industry spent hundreds of millions of dollars fixing leaking showers and other areas.

Now everyone’s being told about cure times, salt staining and bond breakers. What this tells us is that waterproofing strategies and products are getting better and more technical, and we need to stay up with the best choices.

And if you think your know everything, think again…

I haven’t included anything technical about membrane types, different bond breakers, holding down wind exposed membranes, insulation under membranes, detailing ballast or gravel etc. – so please seek advice when you need it.

What you do know now is considerable, mainly because everything in the rules apples to whatever membrane or waterproofing issue you will ever encounter.