Increased use of performance – JP3

Regular readers of the Australian Building Codes Board’s ABR Online will be aware of its ongoing project to quantify all National Construction Code Performance Requirements, which is on schedule to be completed in 2016. This article explains and demonstrates a method of developing an Alternative Solution that complies with Performance Requirement JP3.

The intent of JP3 is to limit the use of a high greenhouse gas (GHG) intensity energy source for heating a conditioned space. It does not prevent the use of electricity because the GHG intensity is related to the thermal load rather than the energy consumption (covered by Performance Requirement JP1).

JP3 also contains the qualification that it is to be applied “to the degree necessary”, allowing electricity to be used, even by low efficiency plant when there are no reasonable alternatives.

JP3

Heating such as for a conditioned space must, to the degree necessary, obtain energy from the following.

(a) A source that has a greenhouse gas intensity that does not exceed 100g CO2-e/MJ of thermal energy load; or

(b) An onsite renewable energy source; or

(c) Another process as reclaimed energy.

Quantification of JP3

Sub-clause (a) contains an acceptable quantified measure of GHG intensity and therefore quantification of performance is inherent.

Sub-clause (b) enables the use of a renewable energy source, which by definition, would not generate GHG emissions and therefore it does not need to be quantified.

Sub-clause (c) enables the use of reclaimed energy which is clearly understood and therefore it does not need to be quantified.

Consequently, the measure of GHG intensity described

in sub-clause (a) can be used to demonstrate that an Alternative Solution complies with that option for compliance with JP3.

Development of an Alternative Solution under JP3 sub-clause (a)

Sub-clause (a) contains a requirement that an energy source has a greenhouse gas intensity that does not exceed 100g CO2-e/MJ of thermal energy load.

This limitation would allow the use of:

Gas and heating oil as an energy source for heating of a conditioned space; or

A combination of electricity and low emission sources such as gas, solar and biomass.

In order to estimate the GHG intensity used by a particular energy source, a series of emissions factors and conversions are required in order to express emissions per thermal energy load appropriately. The emissions factors used in this article are sourced from the National Greenhouse Accounts Factors July 2012, a publication by the Department of Climate Change and Energy Efficiency, specifically for use to estimate GHG emissions for general applications. (Note: Under the Machinery of Government changes the responsibilities of the Department of Climate Change and Energy Efficiency have since moved to the Department of the Environment. See www.climatechange.gov.au/sites/climatechange/files/documents/03_2013/nga-factors.pdf.)

As per this publication, the emissions factors for gaseous and liquid fuels, such as gas and heating oil, reported in kg CO2-e/GJ and converted to g CO2-e/MJ are:

Gas (natural gas distributed in a pipeline) 51.2g CO2-e/MJ.

Heating oil 68.8g CO2-e/MJ.

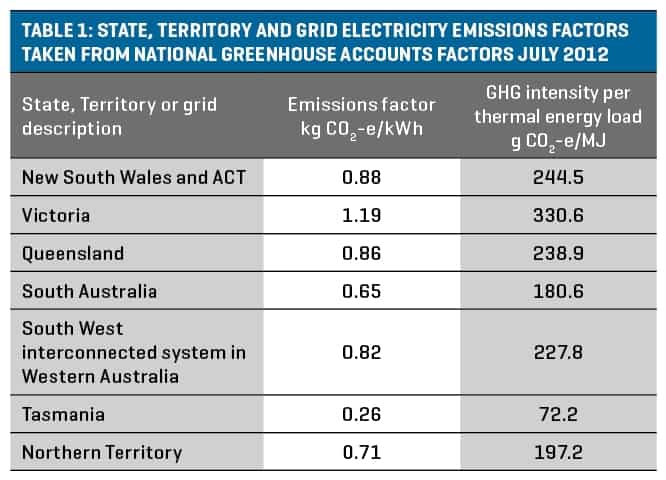

The emissions factors for electricity, based on the state, territory or grid description are reported in kg CO2-e/kWh and have been converted to g CO2-e/MJ in Table 1 on page 16.

In order to convert the emissions factors for gaseous fuels, liquid fuels and electricity into useful quantities it should be noted that:

For gaseous and liquid fuels

1GJ = 1000MJ and 1kg = 1000g

Therefore, 1kg CO2-e/GJ = 1g CO2-e/MJ.

For electricity

1kWh = 3.6MJ and 1kg = 1000g

Therefore, 1kg CO2-e/kWh = 277.8g CO2-e/MJ.

Example: Alternative solution for combined gas and electricity in ACT

Approximately 50% of the energy for heating the conditioned space will be sourced from gas and 50% from electricity. The GHG intensity of this combination would be equal to: GHG intensity of the gas component + GHG intensity of the electricity component.

This sum can be displayed as:

= Percentage of gas component x GHG emissions factor for gas + Percentage of electricity component x GHG emissions factor for electricity.

= (0.5 x 51.2) + (0.5 x 244.5) (g CO2-e/MJ)

= 25.6 + 122.3 (g CO2-e/MJ)

= 147.9g CO2-e/MJ.

This system would not comply as the GHG intensity of the system is greater than that outlined in JP3 of 100g CO2-e/MJ.

However, if the electricity component was reduced to 25% of the total heating energy source, the system would meet the Performance Requirement JP3 (a).

= (0.75 x 51.2) + (0.25 x 244.5) (g CO2-e/MJ)

= 38.4 + 61.1 (g CO2-e/MJ)

= 99.5g CO2-e/MJ.

Development of an Alternative Solution under JP3 sub-clause (b), onsite renewable energy source

The NCC defines renewable energy as “energy that is derived from sources that are regenerated, replenished, or for all practical purposes cannot be depleted and the energy sources include, but are not limited to, solar, wind, hydroelectric, wave action and geothermal.”

Onsite renewable energy sources refer only to those renewable energy sources that are on, or impact upon, the same allotment as the building. Unlike sub-clause (a), sub-clause (b) is clearly defined and allows a renewable energy source to offset the heating for a conditioned space.

For example, installing a 10kW photovoltaic system on the roof could be used to offset a 10kW heater. In this approach the qualification “to the degree necessary” allows the appropriate renewable energy source not only for the size of the heating required, but the location and availability of the types of renewable energy available onsite.

Development of an Alternative Solution under JP3 sub-clause (c), another process as reclaimed energy

Although reclaimed energy, referred to in sub-clause (c) is not defined in the NCC, its meaning is well understood.

Reclaimed energy sources are those that use energy that would otherwise be rejected as waste, such as heat from co-generation, tri-generation or an industrial process. Heat reclaimed through co-generation and tri-generation systems could be used for the heating of conditioned spaces and can assist with reducing GHG emissions.

Co-generation and tri-generation systems typically

Co-generation and tri-generation systems typically

use natural gas or biogas as the fuel for an engine that drives an electric generator. Co-generation systems reclaim waste heat from the engine driving the electric generator and use that energy for heating. Tri-generation systems can be thought of as a co-generation system with some of the heating energy diverted to drive an absorption-cycle chiller. While not yet as common as chillers based on the vapour-compression cycle, absorption-cycle chillers are very economical for supplying a base cooling load where a heat source is available.

Like sub-clause (b), the qualification “to the degree necessary” allows the most appropriate reclaim energy process to be used based on the individual design of the building. Further information regarding onsite renewables and reclaimed energy sources can be found in the Using Onsite Renewable and Reclaimed Energy Sources Handbook available from the ABCB website (www.abcb.gov.au/en/education-events-resources/publications/abcb-handbooks).

As the intent of JP3 is to limit the use of a high GHG intensity energy source for heating a conditioned space, JP3 allows various methods in order to achieve this intent. Alternative Solutions using sub-clauses (a), (b) or (c) would need to ensure the energy source selected adequately met the heating requirements for a particular design. It should be noted that this requirement only applies to heating, not cooling, lighting or other services requiring electricity.

Want to know more about the quantification of performance requirements project?

The ABCB website contains additional details on the increased use and Quantification of NCC Performance Requirements project. Under the Major Initiatives/Quantification of NCC Performance Requirements tab you can access a summary of a recent survey regarding the use of Alternative Solutions throughout Australia, along with details for upcoming education and training opportunities targeting use and understanding the NCC Performance Requirements.

This article was reproduced with permission from the Australian Building Regulation Bulletin (ABRB) 2014. This edition and others can be found on the ABCB website at www.abcb.gov.au/en/education-events-resources/publications/abrb.