New recyclable material could revolutionise construction industry

A breakthrough in recyclable material that could revolutionise the construction industry, assist disaster-affected areas and be used in space exploration has been discovered by a global research team headed by Monash University.

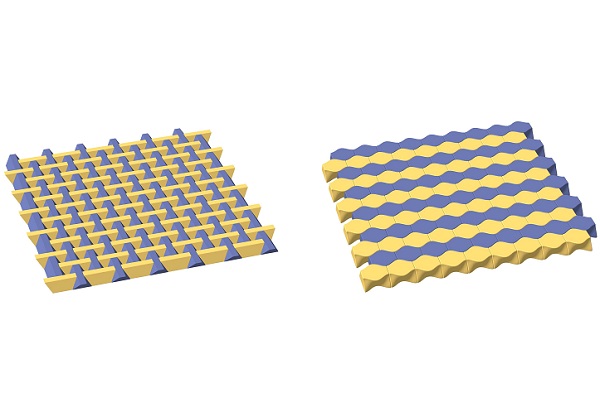

The researchers have developed archimats, an emerging area of ‘architectured’ materials that have an intertwined or interlocked inner architecture. As a result, archimats have an extra degree of freedom expanding the design space that conventional composite materials, such as concrete, cannot possess.

Archimats have enhanced ductility, a high tolerance to damage, good thermal insulation and sound absorption. They can also better absorb energy, as well as provide improved compliance and flexibility.

One of the materials used to achieve this superior property profile, especially through server plastic deformation (SPD) which is a special metalworking technique that results in an ultrafine grain size or nanocrystalline structure. The structural patterns caused by SPD processing can improve the mechanical characteristics and physical properties of materials.

The archimats have potential uses including in construction to reduce the use of concrete and cut carbon dioxide emissions associated with its production, to build or rebuild in arid or disaster-affected zones, in extra-terrestrial and space construction (the European Space Agency is already considering this type of architectured material for the construction of a lunar base and in smart toys and games, such as 2D and 3D puzzles.

“Archimats therefore offer smarter, safer and more sustainable materials for use in manufacturing and industrial design, with the building industry being arguably the greatest potential beneficiary of this design concept,” Monash University honorary professional fellow Yuri Estrin says.

“Archimats are also suitable for micro manufacturing. They can be produced using desktop or benchtop manufacturing processes, without the need for heavy equipment and large amounts of material.

“This opens up new possibilities for industry to explore the use of archimats for application in smart manufacturing, in particular the development of gear for microelectromechanical systems, micro devices and miniaturised drones, as well as superior structural materials for the automotive and aerospace industries.”