UNSW researchers turn clothes into building products

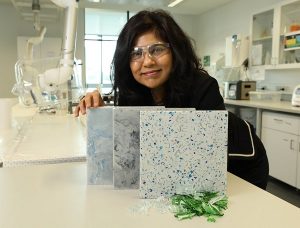

Professor Veena Sahajwalla

Researchers at UNSW Sydney have developed an effective process to turn old clothing and textiles into high-quality building products such as flat panels.

These high-end composite products can have a wood veneer look or a ceramic-style finish and were lab tested for qualities such as fire and water resistance, flexibility, acoustic and load-bearing capabilities but have not undergone any formal regulatory assessment.

Researchers led by Professor Veena Sahajwalla, director of UNSW’s Centre for Sustainable Materials Research and Technology (SMaRT), have been scientifically reforming common waste items using prototype technology developed for a laboratory-scale ‘green microfactory’ to be launched in 2019.

“These newly published results of the wonderful products developed from waste come as an effort to find ways to reduce waste and address our unsustainable landfill problems, which all countries are experiencing,” says Veena.

“It could be said that consumers and the fashion industry have a lot to answer for, given that clothing is now one of the biggest consumer waste streams, with 92MT estimated to be thrown out a year globally. The clothing and textiles industry is the second most polluting sector in the world, accounting for 10% of the world’s total carbon emissions.”

Reforming old clothing and mixed waste glass into various high-quality building products represents a new way to convert low-value waste into high-value products and materials.