Plan it, paper-free

Most construction, plumbing and mechanical subcontractors still connect with other trades via telephone, in person and through email. This makes it hard to track each decision or change that has been made. PlanGrid, an Autodesk company, aims to solve the issue. Justin Felix reports.

We’ve all heard of a paperless office. It’s a growing movement around the globe and aims to greatly reduce or eliminate the use of paper by converting documents via digitisation. Who loves filing cabinets anyway?

Apart from the obvious environmental benefits, there’s merit in going paperless when it comes to efficiency too. Cloud-based documents can be accessed by a team, with any changes updated for all to see in real-time. And if you’ve ever worked with building plans and blueprints you’ll know how frustrating it can be when things change. Not to mention the cumbersome task of lugging plans with you from site to site.

As former construction engineers, PlanGrid’s founders witnessed teams dragged down by paperwork, litigation and broken communication — all of which was getting in the way of actual building.

When the iPad was unveiled in 2010, it marked the first generation of construction field-ready mobile technology. And that’s where the startup kicked off proceedings to make life on construction sites easier and more efficient.

Since its humble beginnings PlanGrid has been used on more than 1.5M projects around the world — from commercial buildings, to freeways, to residential projects. Local examples include Sage Hotel Ringwood in Victoria, and the Pure Construction Management in Sydney (residential).

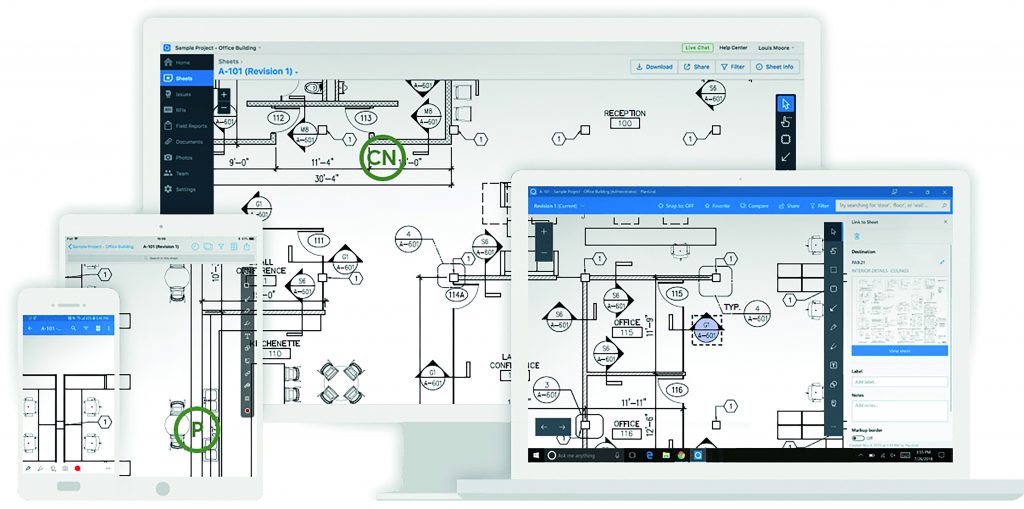

PlanGrid replaces blueprints and other paper documents. You upload them to the platform and hit publish which makes them available to all mobile devices in the field.

Customer feedback has seen the software develop since its inception and users can now take notes and measurements, pin photos and track any issues.

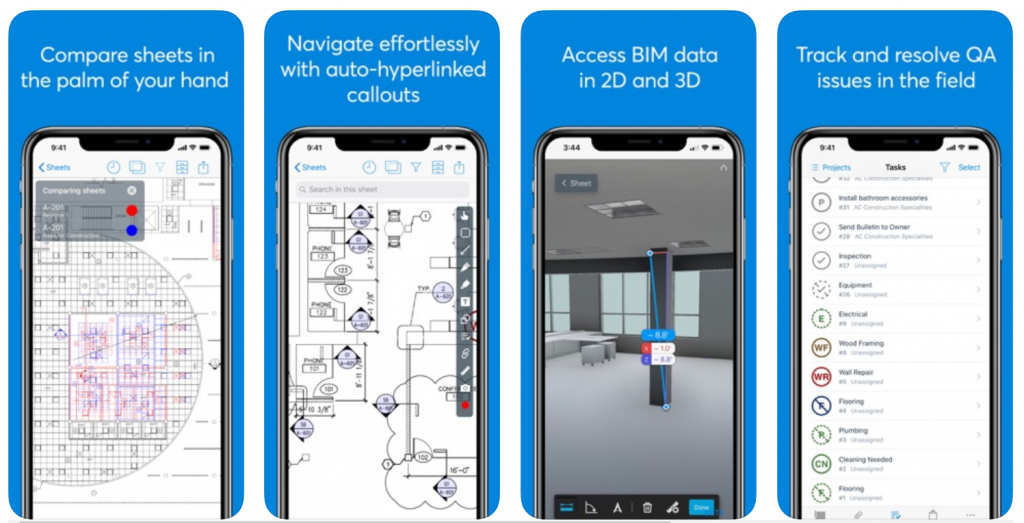

“PlanGrid was designed to be better than paper. If the tool wasn’t better than paper nobody was going to use it,” PlanGrid managing director Asia Pacific operations Praveen Tomy says.

“The team knew it needed to be an app and, from the beginning, worked to make it as user-friendly as possible. As most people have experienced, an app that takes too long to figure out is usually deleted within minutes.”

Rework is a major issue in the industry and if you can eliminate some of it by always working to up-to-date plans, it can add quite a bit of profit to your bottom line.

“From an owner’s viewpoint, at the end of the contract when it’s time for handover, it literally takes a couple of clicks on PlanGrid for the owner to have access to the construction history, photographs, user manuals and product installs.

“They can also see what’s behind walls thanks to photos. Imagine how much value that brings to facility managers,” Praveen says.

The app has gained a lot of traction in the US where it launched and one key observation from the PlanGrid team is just how much subcontractors love it because of the accountability factor.

“Subcontractors will often finish their work before another tradesperson goes in and removes (damages) part of the original work. The unfortunate thing is the finger is then pointed at the original subcontractor.

“Plan Grid allows them to take photos, mark them up and communicate straight to the builder once they’re done. It creates an audit trail. Or proof of workmanship.

“It also provides opportunity to prove work was done to plan (at the time). If plans change and rework is required you need to get paid. This tool provides that audit trail to ensure you do.”

Another key benefit identified by the PlanGrid team is time savings in the field, especially where multiple trades are required to complete a job.

“Think about these regular occurrences on site: plasterers can’t start work until the HVAC systems that go behind it have been installed. Plumbing subcontractors typically can’t install piping until main and branch ductwork has been installed above a ceiling. Mechanical subcontractors can’t install duct work until all the electrical conduits that go behind it have been installed.

“The idea behind productivity software, such as PlanGrid, allows field teams to easily manage their own work and collaborate with the other subcontractors. All the project documentation such as piping, plumbing and plasterboard submittals and HVAC unit cut sheets are available on PlanGrid for easy collaboration,” Praveen says.

It also allows subcontractors to manage off site prefabrication more effectively, as it centralises drawings, data sheets and other project information. This allows them to make changes and markups on the fly while remotely monitoring the work. If their onsite team makes changes to the drawings, the tool should automatically push this data to the offsite precast foam or prefabrications team and vice versa. This is especially critical if the facility is located kilometres away from the project site.

As the digital revolution continues to transform the way businesses operate and become smarter and more efficient, it makes sense that digital drawings are becoming the rule, rather than the exception.

“A digital drawing set lasts for the lifetime of the building,” Praveen says.

“When all the documentation is stored electronically, it creates an easy package to turn over at project completion. This ensures a happy owner and helps secure future projects with them.”