How to avoid thermal breakage

Gary Smith explains what causes thermal stress glass breakage in windows – and what measures you can take to avoid and prevent it.

With the use of thermally efficient glass products on the rise in Australia, it’s becoming increasingly common for the glass in window products to experience thermal stress and to break. If you’re working with glass products, it’s important to understand what thermal stress glass breakage is, and why it occurs.

A thermal breakage is not usually a fault of the glass – it usually occurs as a result of the conditions a pane of glass is exposed to. Some products are more prone to thermal stress than others; this article has been written to help you understand this phenomenon, and reduce and avoid instances of thermal stress and glass breakage.

Thermal stress glass breakage is not something that’s typically covered by a glass supplier’s warranty, so it’s important to understand how you can avoid it.

What is thermal stress glass breakage?

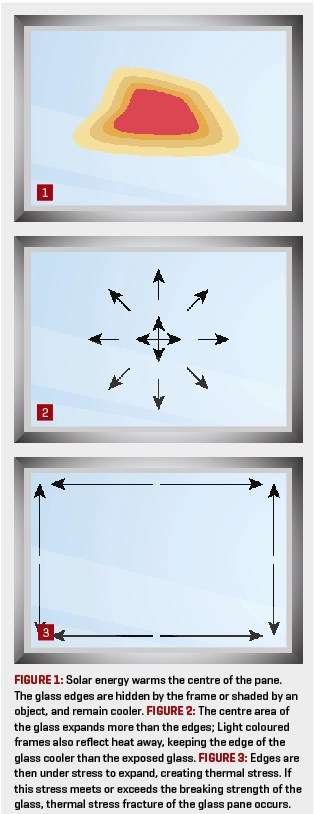

Thermal stress breakage occurs as a result of uneven heating in the glass. When a part of the glass expands with exposure to heat and another part of the glass resists expansion because it’s not being heated, stresses build up in the pane. When the stress is greater than the strength of the glass, a thermal break will occur.

The greater the temperature difference, the greater the thermal stress becomes. Solar energy is the major cause of temperature differences in glass; see figures 1 to 3 over the page for a representation of the process.

Typical conditions where thermal stress breakages occur include:

– A sunny, cold winter day. Typically part of the window may be shaded under an overhang, behind a corner of the building, by a tree, or by a neighbouring building.

– Blinds or drapes reflecting heat back into a sealed unit. If proper clearance between the glass and the blind is not maintained it can exaggerate this problem and overheat the glass.

– When something is placed on the inside of the window, for example a sign or blinds. This can also create the conditions to cause thermal stress.

– A hot, sunny, summer day. This is less common, but can occur especially if heat is being reflected back through the window by blinds or drapes.

– Thermal stress is most commonly seen in glass that retains heat, such as low-E glass, tinted glass, and sometimes reflective glass when the coating is on the #2 side. Tempered / toughened glass is resistant to thermal stress.

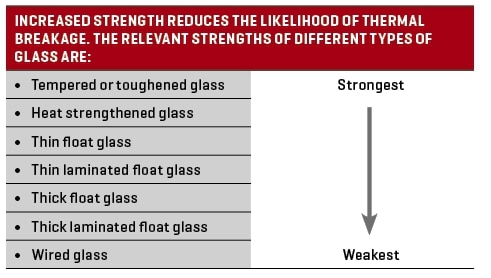

Glass strength and likelihood of thermal breakage

Different glass products have different tolerances, and some products are far more likely to break due to thermal stress than others. It’s important to assess the likelihood of thermal stress when selecting glass types for use.

The information below has been written to help you understand the likelihood of a problem arising when choosing and supplying different products.

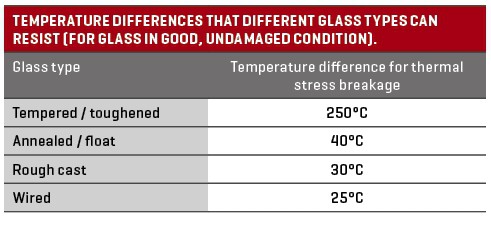

The table below gives some examples of the thermal stress resistance of different types of glass from temperature differences in the glass pane.

Tempered / toughened glass and heat strengthened glass are unlikely to experience excessive thermal stress resulting in breakage. Annealed / float glass products are more likely to experience thermal stress and breakage – this includes laminated float glass products.

Please note that when glass is altered with things like tinting, low-e coatings and reflective coatings, the risk of thermal stress increases. It’s recommended that when using these products, a thermal assessment is undertaken.

How thermal breakage occurs

A window can be fine for a number of years and then one day, when the conditions are just right (or wrong, as it were) it’ll crack. This isn’t something that can be warranted against, because there’s no control over the environmental conditions that cause the problem.

One important factor contributing to thermal breakage is the quality of the edge finish of the glass pane – shells, vents or sharks teeth will add to the likelihood of a thermal breakage. All glass should be supplied as per AS 4667:2000 for glass cutting defect limits.

Some additional factors that may influence thermal breakage are listed below:

– Glass framing that’s in direct contact with concrete or other materials that may contribute to the cooling of the glass edge.

– Excessive coverage of the glass edge by the frame.

– Heat-absorbing films attached to the glass after installation.

– The use of internal shading devices such as curtains, drapes or venetian blinds – If shading devices are used, they must be placed away from the glass to allow for a free flow of air at the glass surface.

– Airflow from room cooling or heating vents directed at the glass. Airflow should be directed away from the glass.

– Buildings not heated during the construction phase may experience an increase in thermal breakage.

Generally speaking, the greater the glass edge area, the greater the risk of thermal breakage.

Recommendations

– Again, if you’re using a product that’s prone to thermal stress (as described above), then a thermal assessment is strongly recommended.

– If you’re concerned about thermal breakage, use toughened or heat strengthened products.

Advise your customers about the possibility of thermal breakage, and explain that it’s not something that’s covered under warranty.

– Speak with your glass supplier for advice and recommendations.

– Ensure care is taken on the edges of high performance glass products – particularly those that are prone to thermal breakage.

– Check the edge quality of products you receive which are known to be prone to thermal breakage, and ensure a high quality finish as per AS 4667:2000. A good clean-cut edge is the best finish, along with fully polished edges. Ground edges and arrissed edges may not be as good. Glass with damaged edges will take less stress than clean cut glass.

If you follow these guidelines, you should be able to avoid thermal breakage.