www.buildingconnection.com.au

www.buildingconnection.com.au

3 3

of the effect they can have on the

environment.

“The positives to moving forward in

a sustainable way are that it breeds

forward-thinking. Society is at a point of

wanting change and each industry must

follow. The benefits fall back into your

pocket,” he says.

So how exactly does it work?

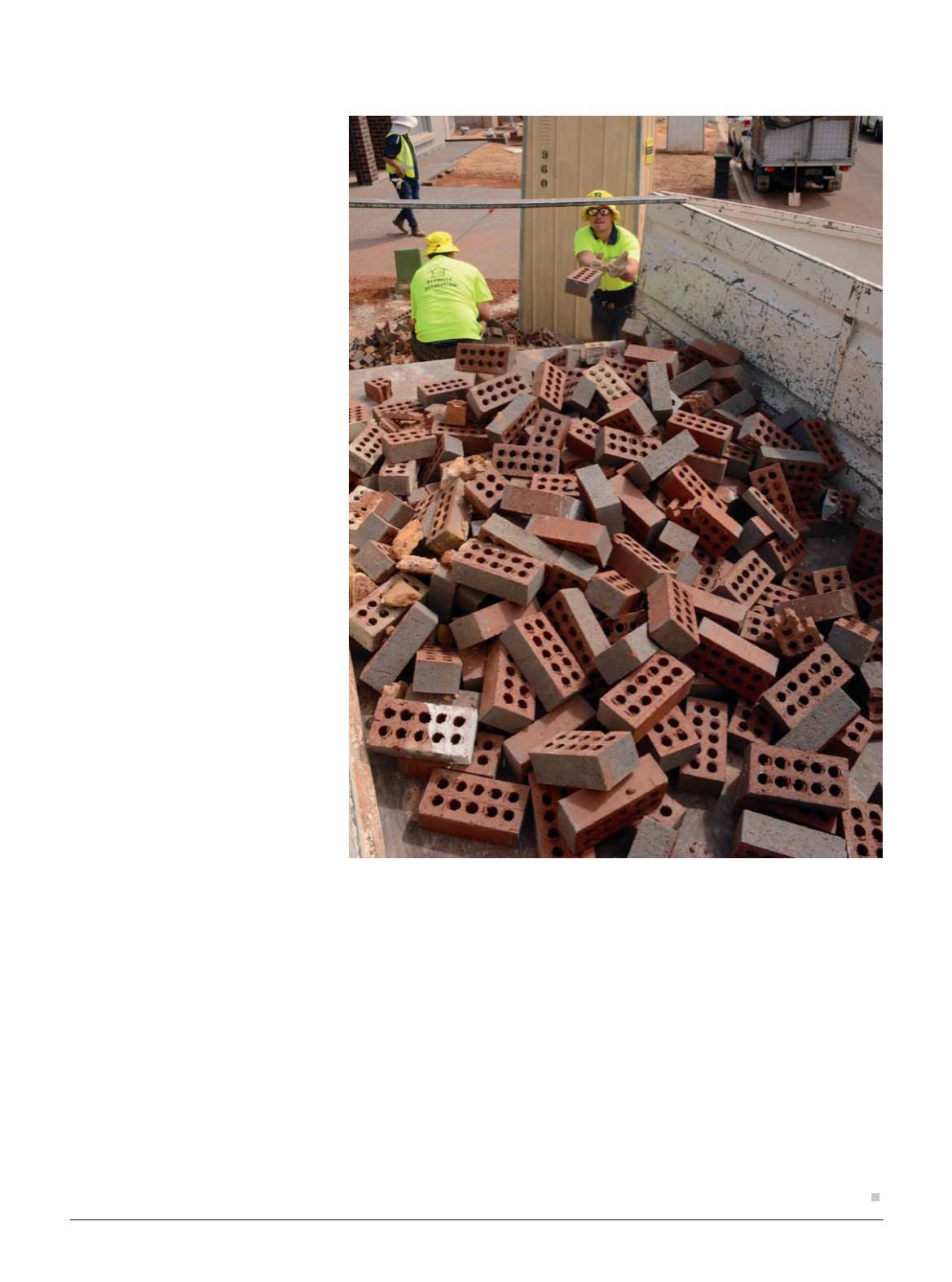

From, once upon a time, seeing skips

full of off-cuts destined for a dump

site, the range of uses for repurposed

material is almost limitless.

“Through six stages of a worksite

clean, we minimise landfill, site

hazards, and CO2 emissions,” says

Ben, explaining that they identify the

important, waste-heavy stages of the

building process. At the end of these

stages, contractors are instructed to

leave off-cuts in a designated area to be

collected by Precycle within 48 hours of

job completion.

“At each stage we do an entire site

clean and feather the bin for any excess

of un-contaminated recyclables.”

Precycle takes timber, bricks, steel,

REO, plastics, concrete and anything

else that could be repurposed. As long

as the material is not contaminated,

Precycle will take it.

It can then be recycled into a wide

variety of items.

“In terms of how the materials are

repurposed, that is completely up to

the body who takes it. For example,

plasterboard is crushed and mixed into

soil. A lot of our timber off-cuts are

being sent to high schools to help future

makers. We are open to anyone who

is willing to reuse our materials in an

environmentally positive way.”

As a model, Precycle is the first of its

kind. Ben says they pride themselves

not only on being environmentally

positive but also on creating a safe

environment for each worksite, and

he believes it is why builders should

consider using a system like Precycle.

“At the end of the day, we help to

facilitate an organised, well maintained

work site. It is not just the practice of

recycling materials that is beneficial; it

is having someone that is responsible

across the board, for the entire build.”

Precycle, he says, removes the need

for labour in cleaning sites as they make

sure the sites are maintained to the

highest order, helping to reduce waste

and material costs.

“Long term relationships mean we

have an understanding of builders’

ordering practices.”

And this knowledge subsequently

leads into creating a more sustainable

process in the building industry,

says Ben who points out that being

an environmentally positive and

sustainable builder has its difficulties.

“Waste is an enormous part of

that. Previously, there were no real

alternatives to the current model of

dumping everything into a skip and

forgetting about it.”

But Precycle is not just about

dumping in an environmentally friendly

way; it’s about reducing the amount

of resources being used from the very

beginning.

“If we can create a circular economy

in the building industry, we can give

back to builders whether it’s materials

they haven’t used, or giving them

an understanding of what they have

consistently over-ordered,” says Ben.

Not only does Precycle’s model encourage recycling, it also creates a cleaner, safer

work environment for everyone working on the jobsite.