BUILDING CONNECTION

SUMMER 2016 15

The Deemed-to-Satisfy referenced construction manual,

which in most cases is the BCA referenced Australian

Standard relevant to the construction, is assessed as being

compliant. AS 3740-2010 is the document, in this case.

Where a Performance Solution is provided, the appointed

certifier must independently READ and ASSESS the

documentary evidence provided as being compliant with the

Performance Provisions.

However, the Performance Provisions are the premium

factor that all Building Solutions must lead back to and

comply with.

Under BCA Vol 2 Part 2.4.1, the Performance Provisions

are:

“To protect the structure of the building and to maintain

the amenity of the occupants, water must be prevented

from penetrating

a. behind fittings and linings; or

b. into concealed spaces of sanitary facilities, bathrooms,

laundries and the like “

STEPS TO DETERMINE MATERIAL SUITABILITY

Following are the steps required in order to assess

the BCA requirements and marry these up with material

suitability, when considering the use of a material such as

welded vinyl in wet areas.

1. BCA states that wet areas are to be made waterproof

or water resistant according to AS 3740 – 2010. A

waterproof material is one that is impervious to liquid

passing through it, such as a glass panel, a receptacle

like a bath or basin, and a waterproof membrane. Water

resistant materials are those that restrict the passage

of water and do not deteriorate when in contact with

moisture. Materials such as ceramic tiles, mortar

screeds, cement based tile adhesives and concrete

are classified as water resistant and are used as lining

materials and intermediate layers acting as ballast and

drainage cells.

2. BCA Table 3.8.1.1, and AS 3740 Table C1 prescribe the

designated wet areas and the components of those wet

areas requiring treatment as either waterproof, water

resistant, or no treatment required. The scheduled wet

areas are:

a. Showers

b. Areas adjacent to baths and spas (Bathrooms, ensuites,

powder rooms etc.)

c. Laundries

d. Toilets

3. Components in the above wet areas are broken down and

a level of protection assigned according to the usage

of that area and the regularity of exposure to water

and water movement. All shower floors and horizontal

surfaces are required to be waterproof. Shower walls are

3:

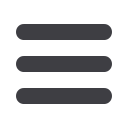

Waterproof membrane to floor and critical wall areas of

shower. Water resistant wall substrate to shower walls.

4:

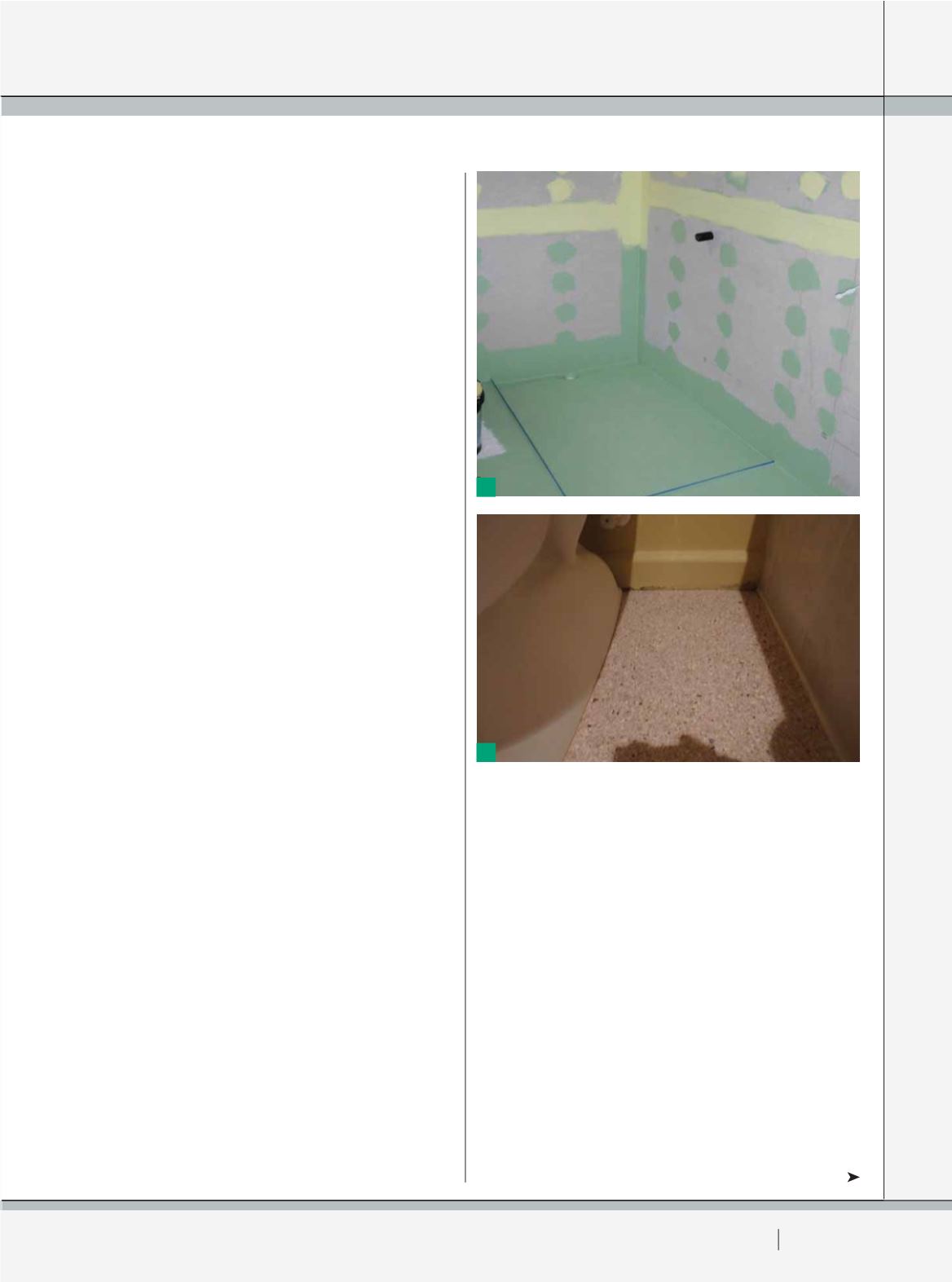

Water damage to non-compliant skirting. All compliant

substrate and lining materials must be in conjunction.

3

4

required to be waterproof only up to 150mm from the floor

with the remainder being water resistant to a minimum of

1800mm from FFL as determined by the rose connection.

Shower wall joints are to be waterproof.

Bathroom, laundry and toilet floors are required to be

water resistant, when on concrete or FC sheeting, and

waterproof when on timber substrate. Wall and floor

junctions are required to be waterproof and sealed to

a water stop at doorways as part of the continuous

perimeter flashing.

4. AS 3740 Section 2 lists compliant materials which

are classified as either waterproof or water resistant.

Section 2.4.2 lists substrate materials that are water

resistant, when used in conjunction with compliant lining

materials. Section 2.4.3 lists compliant lining materials

when used in conjunction with compliant substrate