16

BUILDING CONNECTION

SUMMER 2016

materials. Both substrate and lining materials must be

used in conjunction, or combination; not as a standalone

substrate or lining material. Welded sheet vinyl is

scheduled as a water resistant flooring material that

must be combined with a compliant substrate, but water

resistant only. This is insufficient; where the requirements

listed above, call for waterproof materials for critical

components. Section 2.4.1 also recognises waterproof

welded sheet materials as a compliant waterproof finish,

however this is not referring to welded sheet vinyl, but

is intended to refer to sheet membranes such as: heat

welded PVC sheet membrane, FPO (Flexible Polyolefin)

sheet membrane, TPO (Thermo-plastic Polyolefin) sheet

membrane, Butynol rubber sheet membrane and EPDM

(modified rubber) sheet membranes. If a material is not

scheduled under section 2, then it may not be compliant,

however many builders insist on incorporating materials

such as timber, plaster setting and carpet in wet areas.

These materials should either be removed or protected

from contact with water.

5. Most welded sheet vinyls are classified as water resistant

by their manufacturers, as stated on published technical

data sheets. Therefore, where waterproof systems are

required to shower floors, all timber floors, sealed wall

& floor joints, and sealed wall joints everywhere, we

5

COVER STORY:

TILING DEFECTS

must provide a compatible waterproofing membrane

beneath the water resistant vinyl. Alternatively, install

a waterproof vinyl. There are only a small number of

compliant waterproof welded vinyls on the Australian

market. These are documented with a compliant

CodeMark testing certification, recognised by the ABCB

(Australian Building Codes Board) and tested to AS 4858

– 2004 Wet Area Membranes. Tarkett’s range of welded

vinyls is an example, and is documented as CodeMark

compliant materials. However certification is only issued

when these products are installed by Tarkett qualified

installers and all welds are tested!

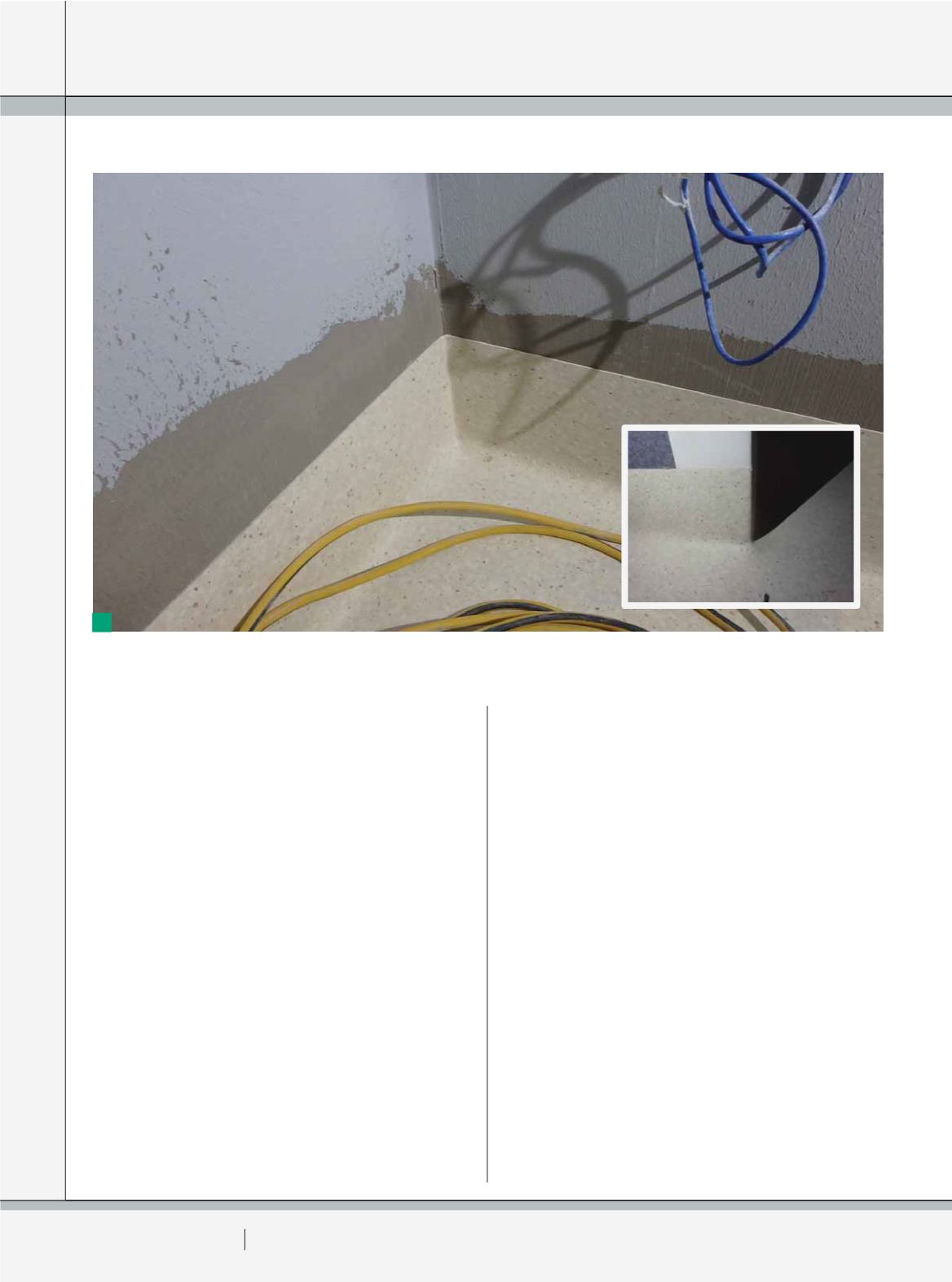

WATERPROOFING MEMBRANE ANDWELDED VINYL

INSTALLATION ISSUES

A number of issues arise when combining waterproofing

membranes and welded vinyls. Quite often defects become

evident, over time where the vinyl begins blistering, membranes

fail and BCA performance breaches occur where water exits

the wet area causing damage to other building elements and

adversely affects the health and amenity of occupants.

These defects can be attributed to faulted installation

practices such as:

1. Incompatibility between waterproofing membranes and

solvent based vinyl adhesives - Water based membranes

5:

Cementitious isolation layer protects waterproofing membrane from incompatible adhesives and installation damage as

with ‘Butterfly ‘ corner cuts.