3 2

BUILDING CONNECTION

SUMMER 2016

BATHROOM PODS MAKE THEIRMARK

P

refab-AUS, the peak organisation for the pre-

fabricated market expects the sector will account for

10% of the overall market by 2020. That’s good news

for the local pod fabricators but it is also attracting offshore

competition, aided by developers and builders taking up the

opportunity to deal direct at foreign labour rates.

On one hand a key benefit being promoted by the local

sector is quality control but when a completed unit is

coming out of China, there is rightful concern about quality

and defects being raised. The local contracting industry also

has concerns about the loss of onsite jobs to the factory

built sector.

As a means of distancing its brand from imports and

other local competitors, NSW-based Interpod has gained

WaterMark Certification for its completed bathroom pod

solutions.

For many plumbers and others across the plumbing

industry, the ability to WaterMark a complete bathroom

installation might come as news as the common market

view is that a WaterMark applies to an individual product.

Plumbing Connection spoke to Interpod business

development manager Stuart Light to update us on the

growth of the local pod market and the dynamics of the

business model.

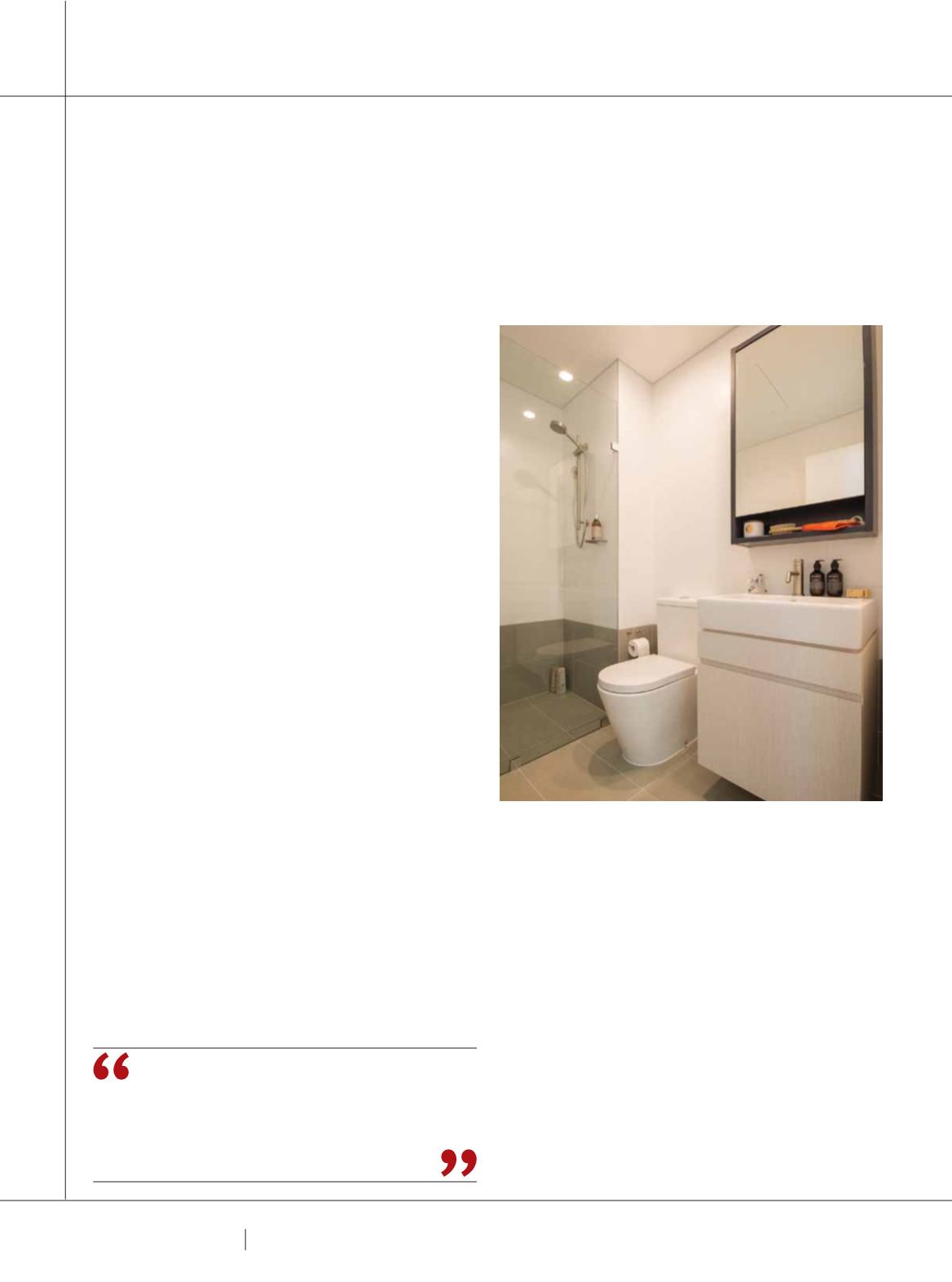

“Interpod bathrooms are complete, prefabricated

modular bathroom pods manufactured offsite ahead

of, or parallel to, the onsite construction schedule. The

Interpod system is designed so that when bathrooms are

installed, they look and feel exactly like any other bathroom.

Built in Australia by licensed Australian tradespeople to

exacting standards, our bathrooms comply with all relevant

Australian Standards (AS) building, plumbing, electrical and

waterproofing codes,” says Interpod business development

manager Stuart Light.

Interpod bathrooms can be used anywhere where

repetitious design makes offsite manufacturing more

THE POPULARITY OF PRE-FABRICATED BATHROOM PODS IS ON THE RISE IN MULTI-RESIDENTIAL AND

COMMERCIAL APPLICATIONS. AND WHILE OFFSHORE-BUILT PODS MAY CAUSE CONCERN WITHIN THE INDUSTRY,

ONE AUSTRALIAN MANUFACTURER IS OFFERING A TOTAL WATERMARK CERTIFICATION ON ALL ITS PRODUCTS.

Pod bathrooms are complete, prefabricated modular

bathrooms manufactured offsite ahead of construction.

PREFAB CONSTRUCTION

efficient. Projects have been completed in many sectors

of construction including hotels, residential apartments,

aged care developments, hospitals and accommodation for

defence personnel.

“Our in-depth cost analysis has provided us with

guidelines for maximising project efficiencies. Through this

process we identified that, in order to achieve a benefit,

projects need to have a minimum of 60 bathrooms with a

ratio of at least 50 bathrooms per bathroom type (ie. if a

project has 200 bathrooms, it must have a maximum of

four bathroom types/layouts). The target ratio is 100:1 or

greater for maximised efficiency and bathrooms should

not exceed 3.0m x 2.3m internally. We have a ‘Designing

for Pods Manual’ on our website, which gives information

to assist with maximising project benefits right from the

design phase,” says Stuart.

THE INTERPOD SYSTEM IS

DESIGNED SO THAT WHEN

BATHROOMS ARE INSTALLED, THEY

LOOK AND FEEL EXACTLY LIKE ANY

OTHER BATHROOM.