2 8

BUILDING CONNECTION

SUMMER 2016

IT’S TIME TO ‘FASCIA’ THE TRUTH

I

t has always amazed me that roofing companies are on

a race to the bottom when it comes to the installation

of metal fascia and gutter. Metal fascia is such a small

part of every home but it is such an important link in the

construction process.

Metal fascia was first introduced into the construction

industry in the early 1980s and at the time a lot of people

said it would never be accepted and that no one would want

it. Here we are, 30-plus years later, and I would say that over

90% of all houses built today feature metal fascia.

Why? The answer is obvious: timber fascia has to be

painted, repainted, and then repainted again only for it

to eventually rot. Colorbond® fascia is produced with the

Colorbond coating already on it and it will usually outlast the

house that it is installed on.

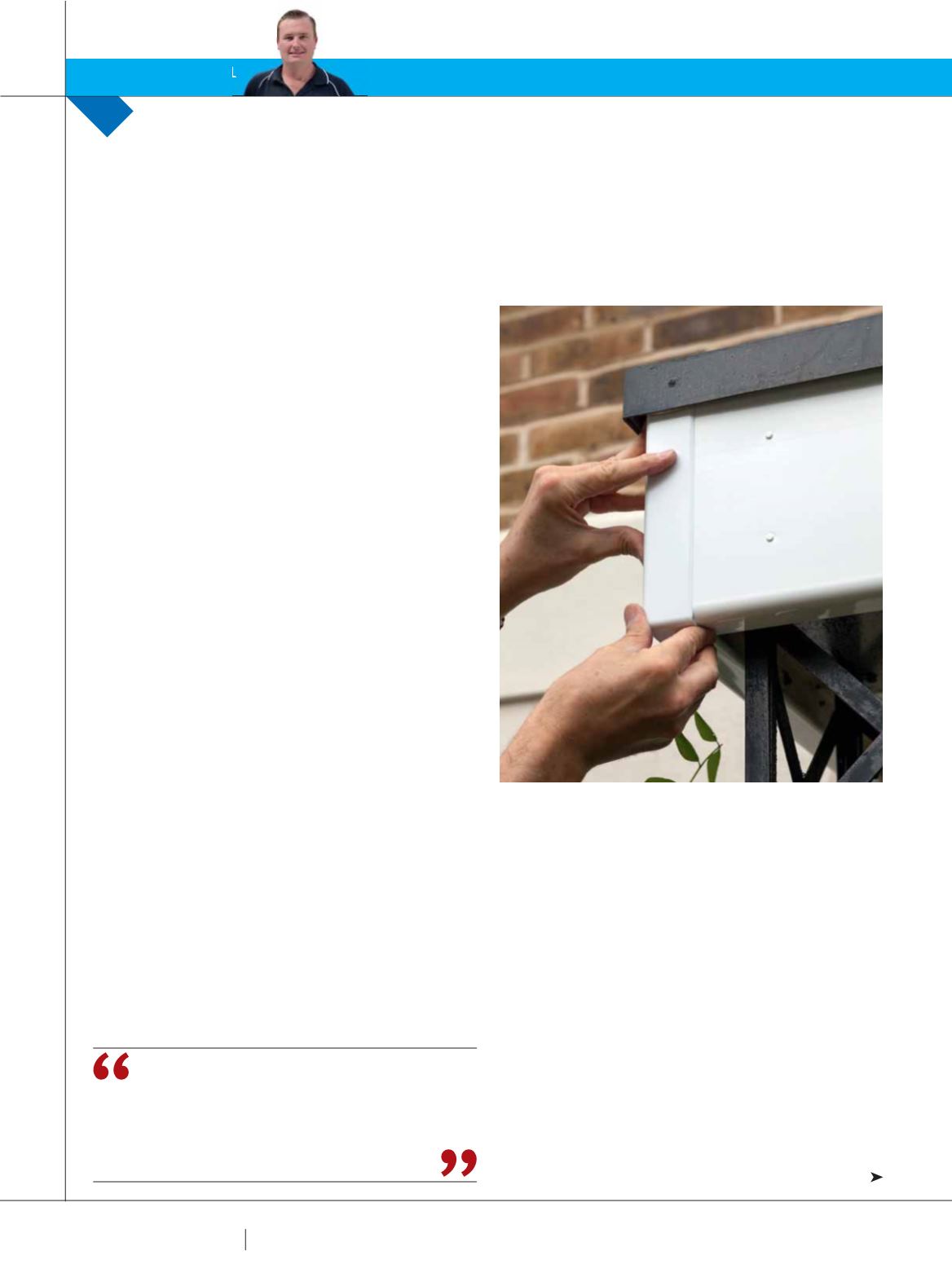

Builders know that the fascia and gutter is a linchpin in the

construction process because it is such a quick installation

and most standard installations are completed in 2-3 hours,

but if for some reason it doesn’t happen, you will find that

it holds up everything scheduled after, including roofing,

bricks, eaves, cladding etc. It is also a really important

aesthetic component to most houses these days as it

frames the look of the entire house.

In the early 1980s roofing companies were installing

metal fascia and gutter for almost the same price they

are now, around $27 per lineal metre in Melbourne, but the

rollformer i.e. Stramit, Stratco, Lysaght etc. have raised

their costs by 150% for the material needed.

The installation rates have also risen by roughly 150%.

That’s not to mention that the overhead and taxes cost

have gone up in that time. At the current rate metal fascia

is the most unprofitable product being sold in the domestic

building marketplace.

In 1983 the installation equation would have looked

something like this:

(Please See Table 1)

Looking at this the profit percentage is probably far too

METAL FASCIA HAS BECOME A BIG COMPONENT OF MOST NEW HOME BUILDS; HOWEVER, RISING MATERIAL COSTS

HAVE MEANT THAT PROFITS ARE SIMPLY NO LONGER THERE.

PETER COLL

EXPLAINS.

Fascia is a linchpin in the construction process.

WHY HAVE ROOFING COMPANIES

ALLOWED A PRODUCT TO BECOME

ESSENTIALLY PROFITLESS?

high, I would love it but I am never going to achieve it.

This is what it look like on today’s calculations.

(Please

See Table 2)

NOTE: these prices are taken from a quick survey of

rollformer’s and from personal memory and may not be

100% accurate.

So I again ask: why have roofing companies allowed a

product to become essentially profitless? I am guessing

that in a large part this is competition driven. In the early

1980s there were 4 or 5 companies installing metal fascia

in Victoria and they all knew each other and life was mostly

amicable, but as we hit the 1990s this number would have

been in the hundreds and now thousands.

As bigger national companies entered the industry with

better processes and buying power, the price dropped

drastically and the industry followed suit; builders became

accustomed to paying less and less. The 90s also saw

METAL ROOFING 101

PETER COLL