BUILDING CONNECTION

SUMMER 2016 33

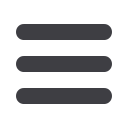

Interpod bathrooms are wrapped in heat shrink wrap for

protection when transporting and when exposed to the

elements onsite. Transporting is generally carried out on

semi-trailers or B-doubles, with deliveries to site being at

pre-determined times to fit in with site programming.

Pods can then be lifted by crane or unloaded using a

forklift to a materials hoist. When craning, pods are landed

on a cantilever deck, and wheeled across the floor to where

they are to be installed. Installation is typically carried out

by the site plasterers, who install the bathrooms as part of

their initial wall set-out. According to Stuart, specialised

handling equipment is provided by Interpod to ensure that

site time is minimised.

“On a recent project in Brisbane with over 600 bathrooms,

crane cycle time was around three minutes per bathroom.

Interpod’s unique lift system ensures crane time is kept to

a minimum, and can reduce crane time by up to 10 minutes

per bathroom when compared with other systems.”

Stuart breaks down the benefits of using pods as follows:

a. For the builder, Interpod de-risks the project, with

opportunity to provide substantial savings (depending

upon the site specifics) in the following areas:

∫

Time:

if bathrooms are on the critical path, this amount

of time can be taken off the overall project programme.

On a recent project with nearly 1,000 bathrooms, 100

bathrooms were supplied and installed per week.

∫

Reduction in waste costs:

no waste is generated from

within the bathroom when pods are incorporated into the

project. Traditional construction of bathrooms will cost up

to $300 per bathroom in waste costs, plus the many hours

of labour required for removal and placement of the waste.

∫

Reduced site management costs:

with fewer trades on

site, management is simplified, and the requirement for

‘finishes foremen’ is greatly reduced.

∫

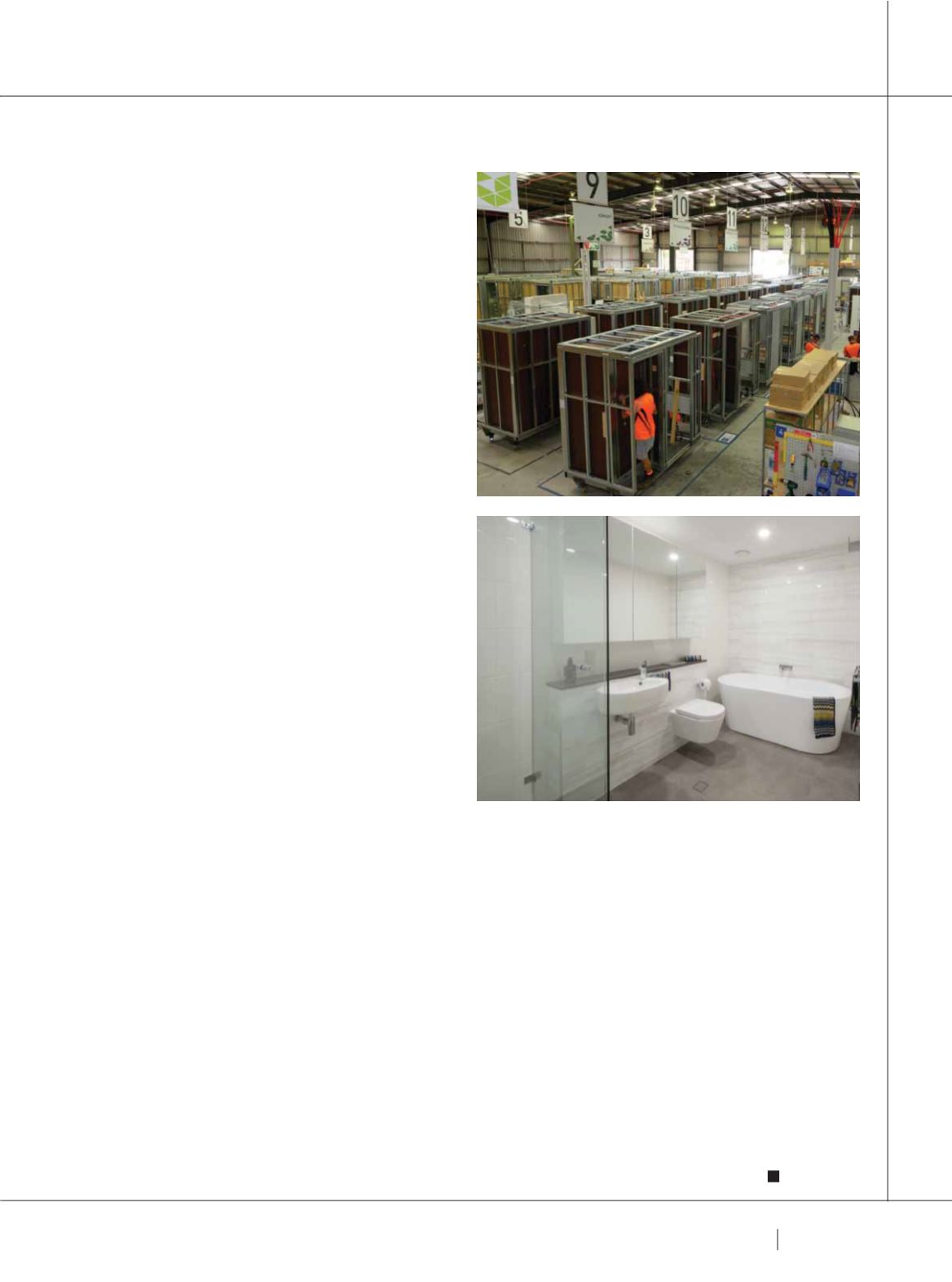

Minimised warranty maintenance:

manufactured to

exacting standards, Interpod bathrooms provide a level of

finish that is second to none. Call backs for: blocked floor

wastes; waterproofing failures; defective workmanship,

etc. are minimised or eliminated due to the structural

integrity of our systems.

b. For the trades, at practical completion of the project, defect

rectification required by bathroom trades is greatly reduced.

This allows the trades to move on to other projects, and the

overall project to be more profitable for each trade.

c. For the developer, the use of prefab bathrooms often

assists with getting the project to market quickly,

providing a better return on investment (ROI).

d. For the owner, ongoing maintenance is significantly

reduced. Because the manufacture of the bathrooms

takes place in a controlled factory environment, quality

is inherent. QA checks are carried out at set points in

production, ensuring that the risk of potential failure or

defect down the track is minimised.

The aim of the WaterMark Certification Scheme is to

ensure products meet AS/NZS specific specifications

and standards, and to assist Australian consumers to

identify quality products. In order to achieve WaterMark

certification, Interpod underwent extensive onsite testing

and auditing. This included working prototypes being tested

in-situ to insure all installation, operation and functional

standards are met.

“The use of Interpod’s WaterMark certified bathrooms

provides assurance of a product that meets or exceeds

every relevant Australian Standard. All pipe work, fittings

and fixtures within the bathroom are installed and certified

by our licensed plumbers, and covered under QA and

WaterMark test procedures. The site plumber can rely on

this certification ensuring that they don’t take on the risk of

works inside the bathroom pod,” says Stuart.

Interpod bathrooms can be used where repetitious design

makes offsite manufacturing more efficient.