2 6

BUILDING CONNECTION

SUMMER 2016

NEW STANDARD SET TO CONTAIN

THE FLAMES

T

he Lacrosse fire in Melbourne’s Docklands in November

2014 has sparked many discussions and calls to

action regarding shoddy non-compliant cladding

materials and adhesives, a lack of adequate testing and the

use of such materials on external facades.

Post incident analysis conducted by the Melbourne Fire

and Emergency Services Board (MFB) revealed that the

southern wall was severely fire damaged with the majority of

the Alucobest wall cladding consumed. Further examination

of the wall components exposed damage to the combustible

components within the panels and, along with foam

lagging and the PVC pipework within the wall, the cladding

contributed to the fire spreading at a rapid rate.

If it weren’t for the building’s fire sprinkler system, it has

been largely agreed upon that the situation would have been

even more severe with loss of lives a real possibility.

Needless to say, change was needed, particularly in the

area of testing external high-rise cladding materials, as well

as a further call to arms to combat the importation of non-

compliant products.

While the National Construction Code currently requires

cladding materials to be fire tested, the acceptability of

external cladding systems has historically been determined

by internal fire tests and/or small scale reaction to fire

tests, involving relatively small fire sources and samples of

restricted size.

Kingspan Insulated Panels has been extremely vocal

in its support for mandatory full-scale fire testing for

high rise cladding and has taken it upon itself to further

educate industry stakeholders in the importance of such a

requirement being enforced.

“With a growing demand for composite cladding

materials and a predicted rise in commercial and multi-level

apartment developments, the need for stringent large-

scale fire testing of cladding materials is a critical safety

measure,” said technical director Kingspan Insulated Panels

Dr Mark Tatam.

“The main issue in Australia is the fact that it hasn’t

had facade tests in place before. There have been tests

developed overseas but nothing has been used here.

Typically we have used small scale tests which aren’t really

appropriate for external facades of buildings and they can

give mixed results.”

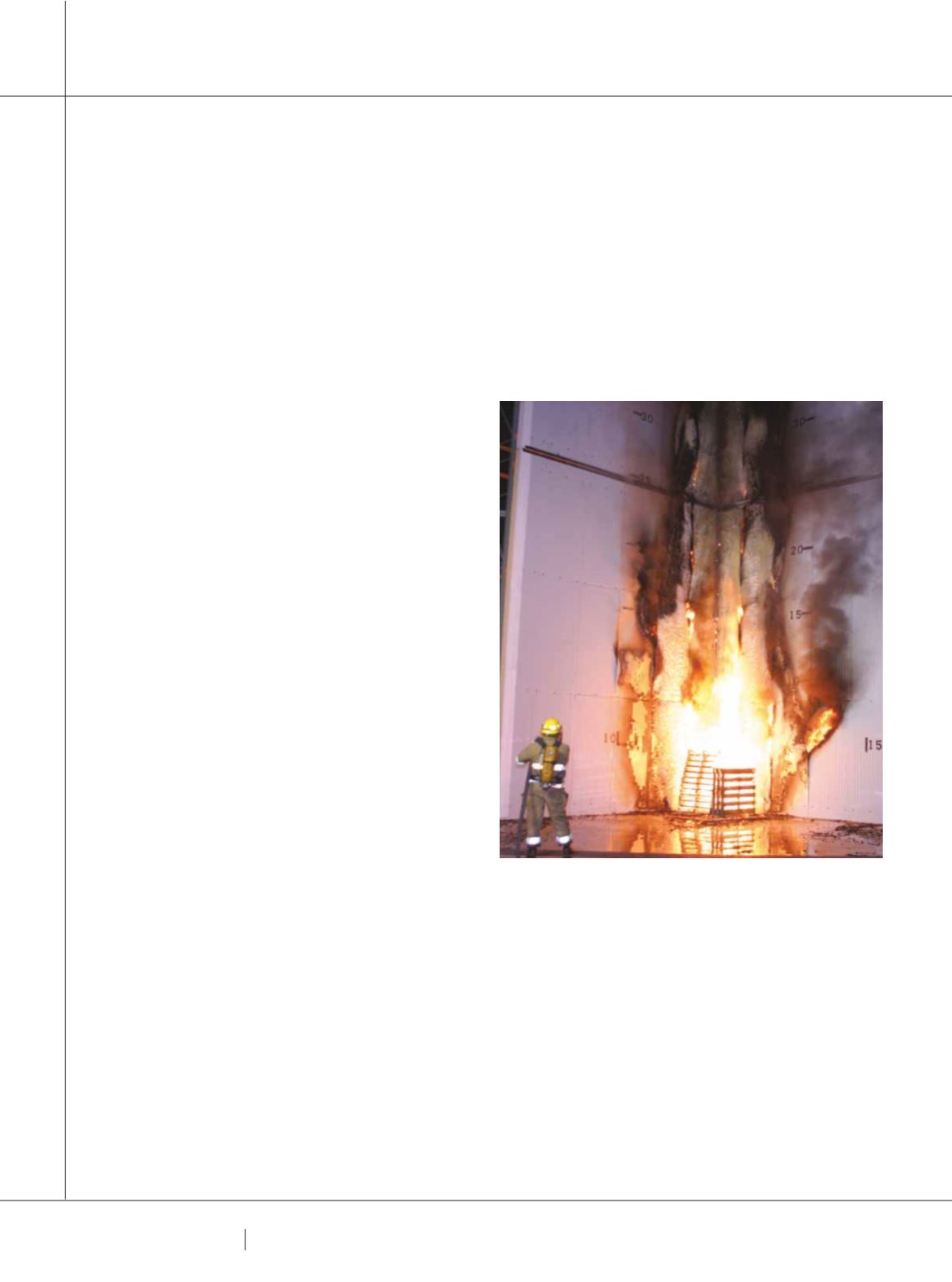

Standards Australia in conjunction with the Australian

Building Codes Board (ABCB) has developed a new

Australian Standard AS 5113

Fire propagation testing and

classification of external walls of buildings

that will provide

a more accurate indication of the fire combustibility of wall

claddings and wall assemblies, as it is based on large-scale

facades fire testing.

The standard sets out procedures for testing and

classification of external walls according to their tendency

to limit the spread of fire across their surface and between

neighbouring buildings. It can be applied to external vertical

STANDARDS AUSTRALIA AND THE AUSTRALIAN BUILDING CODES BOARD HAVE DEVELOPED A NEW STANDARD

THAT IS SET TO IMPROVE FIRE SAFETY THROUGH APPROPRIATE CLASSIFICATION OF THE PERFORMANCE OF

EXTERNAL WALLS, YET MORE WORK IS NEEDED.

JUSTIN FELIX

CAUGHT UP WITH TECHNICAL DIRECTOR KINGSPAN

INSULATED PANELS DR MARK TATAM, AND STANDARDS COMMITTEE MEMBERS, TO DISCUSS THE ISSUE.

CLADDING SYSTEMS

AS 5113 also integrates international standard test

methods, such as this one, where practicable.